Showing 101–150 of 205 results

AA10/220425E/TR-R/M/BY/

RF System Radio Frequency Dryer

Quantity: 1, Year: 2016, mod.TD85H4A, Table width 1800 mm, belt 1560 mm x h.240 mm. Power installed 150 Kw.

AA98/200425D/TO-R/C/

STALAM High Frequency Dryer

Quantity: 1, Year: 2010, model : RF85KW , machine in excellent running condition , very low used, installed power 140 KVA , voltage supply 380/400 , 50/60 Hz ,suitable for cones , bobbins or bumps , height 400 mm. ,

AB76/150425/AA/

Universal Dyeing Machine MCS THYGESEN

Quantity: 2, Year: 2007, bath ratio 1:4-1:5, load 130-150 kgs, complete, connected, working

AB76/150425/AA/

Scholl HT Dyeing Machine

Quantity: 1, Year: 1997, apacity 5700 ltr, load 180 kg, 2 nozzles, pc Sedomat 2000, complete, connected, working

AB76/150425/AA/

Scholl HT Dyeing Machine

Quantity: 1, Year: 1997, Capacity 5700 ltr, load 180 kg, 2 nozzles, pc Sedomat 2000, complete, connected, working

AB76/150425/AA/

MCS MF 1 K HT Dyeing Machine

Quantity: 1, Year: 2004, load 50 kg, pc Arctronic 737XL, complete, connected, working

AB76/150425/AA/

MCS Atmospheric Dyeing Machine

Quantity: 1, Year: 2004, pc CT301-LAN, up to 360 kg load, one rope goes crosswise, complete, connected, working

AB76/150425/AA/

MCS MF 2XJ HT Pressure Dyeing Machine

Quantity: 1, Year: 2004, cap. 11670 ltr, 330 kg load,pc CT301-LAN, bath ratio 1:8, one rope goes crosswise

complete, connected, working

AD26/140425E/YP-O/F/AQ/

Mezzera Jigger

Quantity: 1, Year: 2002, Temperature max 143°C., Width 2200 mm. – Working width 2000 mm., Nominal roller diameter max 500 mm., Electric motorization with programmer for working process control.

AB72/150425/

MCS Jet Dyeing HT

QUANTITY: 2, YEAR 2014, CAPACITY 400 KG. TYPE FL 94 HT 2 TUBE LONG TUBE HIGH TEMP 140C 400 KG CAPACITY, SETEX 737 6878 WITH TERMOELETTRONICA PLC CONTROL PANEL. FITTED WITH CONTINUOUS FILTERING SYSTEM, WITH TWO ADD TANKS AND ONE HIGH LEVEL RESERVE TANK. LIQUOR RATIO 5-1.

AB72/150425/

MCS Jet Dyeing HT

QUANTITY: 1, YEAR 2003, CAPACITY 400 KG. YEAR 2004, TYPE: FL 94 HT, 2 TUBE, LONG TUBE HIGH TEMP 144C, 400 KG CAPACITY, SETEX 737 5452 WITH TERMOELETTRONICA PLC CONTROL PANEL. FITTED WITH CONTINUOUS FILTERING SYSTEM, WITH TWO ADD TANKS AND ONE HIGH LEVEL RESERVE TANK. LIQUOR RATIO 5-1.

AA10/140425/

BRAZZOLI Overflow

Quantity: 1, Year: 2011, mod.INNOLAB HT 25 , 1 sample, capacity 25 kgs., 1300 lts., Setex 777 programmer.

AB76/080425/

THIES TRD 140/3

Qauantity: 450 kg, Year: 1998, 3 tubes, 3 ropes, machine can dye with 1, 2 or 3 tubes, 140oC, controller T737XL

AB55/070425/

Master Indigo Dyeing Line

Year: Installed: 2004 (Dye vats and padders manufactured in 1994 and reconditioned by Master when the line was extended and installed in 2004)

Roller Width: 1800mm

Purpose: Continuous dyeing and treatment for modern denims, including mercerising, bottoming, topping, sulphur dyeing, and classic indigo blue, designed for maximum flexibility.

Components:

Beam Creels (2 units):

Maximum 14 beams of 1400mm diameter

One creel can be prepared while the other is running for maximum efficiency

Automatic yarn tension adjuster

Yarn pulling and feeding element

Mercerising/Wetting Process:

Soda process or pre-dyeing vat with padder

6 steam heated, PTFE-coated timing cans (800mm dia.) for mercerising

Fixing or 2nd wetting or washing vat with stainless steel tank and mangle.

Dyeing Section:

Neutralising or washing vat

Washing vat with stainless steel tank and padder

6 dyeing vats with stainless steel tank, intermediate padders, and overhead oxidising roller arrangement with finned stainless steel rollers and dancing roller

Counter current dye circulation system with filters, dosing, and pumps

Circulation tank for indigo

Overhead-mounted steamer for colour denim/oxidiser for indigo.

Post-Dyeing Treatment:

3 washing or post-dyeing treatment vats with intermediate padders

Accumulator for automatic storage of dyed yarn during beam changes (150m capacity, 5 minutes at 30m/min)

Drying cylinder pre-dryer range with 10 PTFE-coated drying cylinders

Sizing Section (Karl Mayer-Rotal, 2002):

Sizing box with prewetting (double dip, double nip)

Drying cylinder range with 14 PTFE-coated drying cylinders

Warp beaming head:

Roller width 2840mm

Maximum beam width 240cm between flanges

Maximum weaving beam diameter 1600mm

Size Preparation Kitchen:

Indigo dye & chemicals storage system:

2 tanks for chemical bath pretreatment

5 indigo tanks

1 sulphur black tank

3 stocking tanks for indigo

1 tank for softened water

Other Features:

Canopies

Electrical control panels

AG52/040425/AG/

N/A IPR Indigo

Quantity: 1, Year: 2012, Type: DOSING SYSTEM INDIGO PREREDUCIDO (2 TANKS de 50 MPEACH)

AB76/250325/

Thies Mini-Soft-Speicher 40 HP Dyeing Machine

Quantity: 1, Year: 2004, T505 controller (2 tubes, 40 kg each)

AB76/250325/

Jigger MCS-MARTELLI brushless 110 C T.2000

Quantity: 1, Year: 2009, pc Termoelettronica.

AB72/190325/

MCS Jet Dyeing HT

QUANTITY: 1, YEAR: 2013, CAPACITY: 500KG, 2 TUBES 200 KG PER TUBE, TYPE DYN EF 2XJ HT ROUND TYPE. DESIGN PRESSURE: 3 BAR.

AC44/070325/

MCS Rope Dyeing Machine 150 Kgs

Quantity: 1, Year: 2000, Brand: MCS / Italy, Model: MF-2 . H.T., Capacity: 150 Kgs.

AC44/070325/

MCS Rope Dyeing Machine 300 Kgs

Quantity: 1, Year: 2000, Brand: MCS / Italy, Model: MF-4 . H.T. Capacity: 300 Kgs.

AC44/070325/

MCS Rope Dyeing Machine 450 Kgs

Quantity: 1, Year: 1999, Model: MF-4J. H.T. Capacity: 450 Kgs

AC44/070325/

MCS HT Jigger

Quantity: 1, Year: 2019, ww 330cm, 1200 meter fabric capacity for 350 gr/mt

AC93/260225/

Vald Henriksen HT Jigger Dyeing

QUANTITY: 1, YEAR 1996, MODEL HT-JIGGER 2000, CONTENTS 10.000 L.

AA94/250225E/CC-R/F/

Laip Hank Dyeing Cabinet

Quantity: 1, Year: 1998, Type ATM.208, 50 Kg Wool, temp. 108°C, 0,4 atm, electron. program Thermoelectronica CT.200, Very good condition.

AG96/210225D/AS.L-O/F/

Stalam Radio Frequency with “”ONE NEW SPARE LAMP””

Quantity: 1, Year: 1992, Width 1200mm, 30KW, Water Cooled, With “”ONE NEW SPARE LAMP””, Good condition, can start to check.

AE56/170225/

Fongs Atmospheric Dyeing Machine

Quantity: 1, Year: 2016, 6 tube 1800kg, 2008,3 tube 750kg, Fongs FC28 Controller,danfoss invertor

Fongs PLC,Max.temperature 100 degree,, heat exchanger,, 1 chemical tank.

AE56/180225/BA/

Fong’s Air Flow Dyeing

Quantity: 12, Year: 2014/2015, FC30 computer

Original parts, Each tube 250kg, Running condition

AE56/180225D/YR-Y/F/BA/

3 tubes 3 sets

AE56/180225D/LO-O/F/BA/

4 tubes 5 sets

AE56/180225D/PT-P/F/BA/

6 tubes 4 sets

AE56/180225/BA/

Fongs HT Dyeing Machine

Model HSJ

Year: 2011-2013, machine stopped now

AE56/180225D/AOP-AI/F/BA/

8 tube 2000kg 3 set

AE56/180225D/ART-AI/F/BA/

6 tube 1500kg 4 set

AE56/180225D/SY-AI/F/BA/

4 tube 1000kg 4 set

AE56/180225D/OR-AI/F/BA/

3 tube 750kg 5 set

AE56/180225D/LC-AI/F/BA/

2 tube 500kg 6 set

AE56/180225D/RC-AI/F/BA/

1 tube 250kg 1 set

AA10/070225/

Thies Jet TRD Dyeing

Quantity: 3

1x Year: 2018, 2 tubes, 150 kgs. each tube, with Controller SETEX 737XL.

2x Year: 2018, 3 tubes, 150 kgs. each tube, with Controller SETEX 737XL.

AA10/070225/

Thies Long Pipe Jet Dyeing

Quantity: 1, Year: 1997, mod.Soft TRD

3 ropes, load capacity 180Kg / rope total 560kg, possibility to select to run ONLY 1 rope (180kg), 2 ropes (360kg), 3 ropes (560Kg), wariojet nozzles, controller Setex 575c, motors with inverter, suitable for woven and knitted fabrics

AA10/070225/

Thies Long Pipe Jet Dyeing

Quantity: 1, Year: 2000,mod. Soft TRD , 2 ropes, load capacity 170Kg / rope total 340kg, possibility to exclude 1 tube / rope, wariojet nozzles, controller Setex 737XL, motors with inverter, suitable for woven and knitted fabrics.

AA10/070225/

Thies Air Jet Dyeing

Quantity: 2, Year: 1999, model AIRSTREAM

2+2 ropes coupled, load capacity 200 kg/rope – total load capacity 400+400 kg, controller Setex 737XL, suitable for woven and knit fabrics

AA10/040225/

VOLLENWEIDER Singeing Machine

Quantity: 1, Year: 2000, mod. MSC4

working width 2000 mm, feeding from jumbo roll or folded fabric, j-box, 4 singeing ramps, wet filter, framing with ambient air-cooling cylinders, impregnation unit with 6+7 cylinders, squeezing padder, tangential winder on jumbo roll, 1 supply tank for recipe.

AI41/050225/

NSC Rebreaker, Converter & RF Dryer

AI41/050225D/YR-P/M/

1x NSC Re-breaker, Model R5A GC 15 RE, Year: 1999.

AI41/050225D/SL-AI/M/

1x NSC Acrylic Tow to Tops Converter, Model TB10.

AI41/050225/

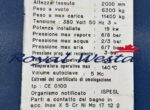

1x Monga Stray Field RF Dryer., model SO-25T

All the machines are available in running condition .

AA10/040225/

MEZZERA Jigger

Quantity: 1, Year: 2002, mod. CELSIUS 143 HT

max temperature 143°C, table width 2200 mm, w.width 2000 mm, nominal roller diameter max 1150 mm, electronic motorization with programmer for working process control.

AE34/280125E/CS-Y/M/

YARN BOBBIN EXTRACTOR MACHINE

QUANTITY :1

YEAR: 2011

ORIGIN SWITZERLAND

MODEL HYDROC-8 / HYDRO EXTRACTOR

BOBBINS CAPACITY: 8 PIECES (8x1kg) Bobbin Diameters: max. 145mm Bobbin height: 200-290mm

PRODUCTION CAPACITIES: 320-400 Bobbins per hour

ELECTRICTY/ POWER: 400V AC 3/PE-22 kW /50HZ , 25.3kW/60HZ

WATER OUTLET: 1

CONDITION IN WORKING CONDITION

AC94/240125/

Fiber (Stock) Dye Plant

Year: 1985~2007

Consisting of:

1x HERGETH Bale Opener – 1986 year, 1500mm working width, Extended feed apron,Mixing Chamber.

2x AUTEFA Cake Presses – 1986 year.

1x THIES Dosing Station type MPS-L – 2007 year.

2x THIES Dye Vessels type Eco-bloc F 1250 – 1986 year (rebuilt 2007), 500kg capacity each.

1x MUHLMANN Centrifuge – 2007 year, 400kg, 1200mm drum ø.

AB55/240125E/APS-AY/M/BB/

Menzel CPB, Cold Pad Batch Dyeing

Quantity: 1, Year: 2018, Upper roller width 3.400 mm, comprising out of high fabric feeding, edge uncurlers make ERHARDT & LEIMER type KF 2020, separate motor driven unwinder and winder, feeding via above the dye rollers installed bow rollers for even feeding into horizontal installed dye rollers, dip vat with displacement roller, exit onto separate driven A-frame roller, Visualisation, preparation tanks, pump.

Almost brand new very less used. Machine is still installed.

AA02/220125D/YPI-RI/M/

Fiber and Tow Dyeing Line

Automatic Fiber Cake Pressing Lines for Fiber Dyeing & Bleach Processing.

All Equipment is NEW and never in production, year 2012.

Quantity: 2 lines

Cake pressing:

1x (New) Obermaier Reserves with Belt Weighing

Model PSW 1500, Working with 2000mm, 1500 kg/hr with 750kg storage capacity, Load Cells, Control Panels, Reserve with condenser, Suction fan, 4m feed belt, Inclined spiked apron, Volumetric feeding, Weighing belt, Transfer belt

1x (New) Stiavelli Irio Fans

Type XVA 561 / N9A, CPCB RDO, 2746 rpm / 11kw

1x (New) Obermaier Automatic Hydraulic Cake Presses

Model HP 1200, Press frame / Press carrier with turntable, 2 Filling Frames with chute and rotary opener with dust screen, Auto lift plate, 6 Transport baskets, 3 Cakes per basket, 2 Blowers / 10200 M³/Hour, Year: 2012

1x (New) Obermaier Cake Press Control Panels

Year 2012

6x (New) Obermaier Material Carriers & Handling Equipment

Model MC 1630/3, 3 x 330kg capacity each, Perforated basket with lid, Single wall, Outer Æ 1570mm / Core Æ 440mm, Height 2850mm, Year 2012

1x (New) Obermaier Hydraulic Fiber Cake Ejectors

Model CL 1500, Lifting frame, Hydraulic unit with 4 lifting cylinders, Pneumatic carrier clamping unit, Year 2012

1x (New) Obermaier Cake Ejector Control Panels

Year 2012

AG54/170125/

Dettin Yarn Dyeing

100kg machinery (1 material holder is dyed), 2 gear holders with 14 lances,, maximum coil diameter 20 cm.

300 kg machinery (1 material holder is dyed), 2 material holders with 27 lances,, maximum coil diameter 20cm

2 material holders with 42 lances,maximum coil diameter 10 cm.600 kg machinery (2 material carriers are dyed)

4 material holders with 27 lances,maximum coil diameter 20 cm.

2 material holders with 42 lances,maximum coil diameter 10 cm.

AC93/140125/

Monforts Thermosol Dyeing Range

Quantity: 1, Year: 1997, working width 2.000 mm, high entry, j-scray accumulator

dyeing kusters padder 222.11.2000, oxidation passage, infra red dryer, gas heated

monforts hot flue, gas heated, 2 chambers, total cloth content 80 m, 2 x cooling cylinders

accumulator, exit to a-frame batcher, machine in perfect condition. Still running.

AA02/110125D/LA-R/M/

Scholl Jets

Quantity: 2, Year: 1×1997 – 1×1998, Rebuilt 2006, Model Colorstar.

All equipped with actively supported Adaptive Controls 1000. capacity 80mm,65mm,50mm / interchangeable.

Best for: Fabrics requiring precise dyeing with advanced control systems, suitable for high-value or intricate textiles.

Specialty: The Colorstar series is designed for precision dyeing, with adaptive controls that ensure highly accurate dyeing results. These machines are rebuilt with modern controls, making them efficient and cost-effective despite their older build dates.

Capacity: Like the Rapidflex, the Colorstar models have interchangeable capabilities (80mm, 65mm, 50mm) and are built for high-volume dyeing.

Technology: The adaptive control systems on these machines help optimize the dyeing process, reducing waste and improving color consistency.

Ideal for: Manufacturers who need precise control over the dyeing process for intricate or high-value fabrics.