AA10/131025E/RS-Y/M/

Volkmann VTS05 2×1 Twister

Quantity: 1, Year: 1986, Type VTS-05, 96 Spindles, Exit cone 10” – 3°30.Note: The machine is complete with software

AH82/131025D/YSL-YL/F/BC/

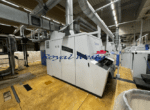

Oerlikon-Barmag Texturizing EAFK-PET(Site C)

Quantity: 1

Model “EAFK-PET”

Year 2017 October, 288sp,

SZ function (double disc friction)

Inverter type, Auto-doffing.

Two Heaters

Additional tech details:

1- The machine is 2 sides, it means side A and side B, separately, LH+RH.

2- The machine JETS are Heberlein brand

3- INVERTER,

There are two typed of driving system as below:

(1). Individual Spindle Drive (e.g., Barmag FK, EFK, E-AFK, etc.) Structure and Control: Each spindle is driven individually by

a disc motor and controlled by an inverter (frequency converter).

The inverter regulates the rotation speed and torque for each spindle separately.

(2). Belt-Driven System (e.g., Murata 33H) Structure and Control: All spindles are driven by a single motor through a common belt system.

Speed is uniform across all spindles and is controlled by the main motor speed.

4- The RANGE OF DENIERS that these machines do range from 30 to 300d.

(1). Factory where the machine is mostly producing 75d and 150d, specially 300d.

for example 850rpm x 150d x 288sp x 24h x60 min. / 9,000 / 1,000 = 5,875.2 Kg x 30 days= 176,256Kg monthly per machine 288sp.

(2). With S-Z function(double disc), possible to produce 600d.

(In case of production for 600d with 300d by S-Z function,

productivity is 1.8 times higher than standard operation)

(3). In case of production with lycra device, productivity will be

decreased by 10 to 15%.

5- machine is made in China by Barmag of Germany (Assembled in China but with all key parts from Oerlikon-Barmag, Germany.)

6- This machine is in a SITE called SITE [C] and is in full running in excellent condition.

7- Machine can be inspected under power

8- machine is multispindles.

9- Heaters to be operated independently, so possible to work with single heater or two heaters

10- Machine has better quality PU type disc instead of ceramic disc.

AB46/091025/

Rieter Open end R40

Quantity: 2, Year: 2005, Each comprising:, 280 rotors each, 2 piecers, Uster Qutntum 2 clearers, Rotor 36mm, Combing roller B174DN, Spiral navel, waxing

AE72/101025/

SAURER ZINSER 451 IMPACT SPINNING MACHINE

Quantity: 2, Year: 2018, 576 SPINDLES, WITH MAGITEX BLOWER, GAUGE 75, RING 45, TUBE 220

AE72/101025/

Finisher SANT’ANDREA NOVARA

Quantity: 2, Year: 2002, Model: RF4/A , 16 HEADS, RACK X 32 , POTS 800X 1200

AE72/101025/

Sant Andrea Breaker & Rebreaker

Breaker Sant Andrea 2MD

Quantity: 1, Year: 1997, Can 700×1000

Rebreaker Sant Andrea CSN

Quantity: 1, Year: 1994, Can 700×1000

AC29/091025D/TI-AI/M/AS/

Zinser 421E Ring

Quantity: 4, Year: 1996-1997, 1088 spindles, 55 diameter, Good quality.

AB45/101025/BY/

Savio Orion Winders

Quantity: 4 , Year: 2002 , model I – EX LINK CONER, nos. 32 spindles , Exit 6” 4°20′, Drum 2.5 assymetrical , Mesdan splicer 590 L

Waxing predisposed, Loepfe yarn master TK 940 BD clearers, Traveller Cleaner , 380 V 50 Hz , Condition:Mill Floor

AI08/071025D/ARC-O/F/BA/

NSC Schlumberger Era Combers

Quantity: 2, Year: 2004-2006.

the feeding creel is 24 ends bobbin condition, it also can feed by can surely if you want.

the delivery can is 1000*1200mm;

the machine can run if customer inspect.

AC94/081025E/AOL-AI/F/BY/

Barmag Tape Extrusion Line

Year: 2007, Type FB7/9-1300-M ,Automatic continuous gravimetric dosing units for 6 components, Extruder Type 9E107 – 350 kg/hr production, Cutting Device In-line gear pumps GCH18K, Cooling bath Type KBF1/1400, Extraction Unit, Stretching unit 1 – 7 cylinders (280mm Ø), Water Stretching – Channel Type TKV 140/4000, Stretching unit 2- 5 cylinders (280mm Ø), Hot Air Oven Type TKD 150/4000 , Stretching unit 3 – 4 hot cylinders (350mm Ø), Stretching unit 4 – 4 cooling cylinders (350mm Ø), Controls, Sahm Winders Type 700XE (160 heads), Status: Stopped Sept 2025.

Note: the winders that are included in the offer are currently in storage. They were originally running on the line but were replaced approx 5 years ago.

The line is for monofilament, not tape. And there is no fibrillation unit.

Note:

the line produced HDPE and PP from 300 -2.200 Dennie. They usually produced 600- 2.200.

they were running monofilament – not sure about tape

Stopped last week Sept 2025 – still hooked to power.

Line layout is shown on the LINK/

AI80/071025/BA/

Barmag FD6-1000 Texturizing

Quantity: 7, Year: 2011, 288 spindles, Perfectly running in PBT+PET YARN in FINE deniers.

AC09/071025/

Open End Spinning Saurer Autocoro 8

Quantity: 2, Year: 2014, No of Rotors: 480, Type of Spinbox:SE 20, Yarn Clearer Make: Corolab, Measuring Head Type: XQ, Rotor Type: TB633BD, Rotor Diameter in mm 33, Type of Drum: SRZ, Opening Roller Type: S21DN, Naval Type: KSK6A, Conicity:Cylindrical, Waxing: Available, Multilot:3, Torque Stop: White TS30-3/W, No of Piecer Carriage: 4, E DriveAvailable

AC94/081025D/RAI-AL/M/AT/

Barmag Texturizing

Quantity: 1, Year: 2017, Type eAFK-PES, 2 heaters, Autodoffing, 288 positions, Denier range: 22~330, Unitens tensioning, Air Entangling, Individual motor friction disc drives.

Machine is 2 sided as shown in the pictures.

Please see on the LINK, the “Scope of Supply”.

Please download PDF files to see more details and pictures.

The machines monitors/controls/displays/Catalogs/Manuals are in English.

AB46/081025/BJ/

Murata 21C Link Coner For Ringframe

Quantity: 33, No of Drums: 20, Yarn Clearer: Lopfe Yarn Master, Measuring head: TK 930S

FD Channel: Available, Splicer Nozzle: G2Z, Waxing: Available, Doffer: 21 DII, Hot Air discharge: Upwards, Suction: Central

Please note machines area stopped on mill, Floor and in excellent conditions

AB45/081025E/CA-Y/F/AQ/

Fadis Doubling Machine

Quantity: 1, Year: 1997, model TUAN BE, nos. 36 spindles, Without Automatic doffer, Exit cone 8”, Conometer, Creel 3 ply, 380 V 50HZ, Condition: dismantled. Need 1 container 40.

AA10/061025/

ICBT Two-for-one Twister

Quantity: 1, Year: 1998, Type DT510, 72 spindles, Feeding 10”, can diameter 330 mm, delivery 10”, independent drive, without air threading device.

AA10/061025/

Oerlikon Saurer Double Twisting 2×1 Frame

Quantity: 1, Year: 2012, mod. 05-0, type 8.02 , 40 heads (20×2), feeding 10″, free ballon, can dia.350 mm., delivery 10″, pneumatic air threading device, pneumatic doffing.

AG15/061025/BC/

Barmag Texturizing

Quantity: 2, Year : 2014, Model : eAFK , No of spindle : 288sp, 2 heaters , V-type , Belt driver , Two side , Single Creel, but can produce SZ (144 spindles). No Lycra device , Semi- automatic doffing , DTY machine of eEFK standard have the function of doff timer. s.z function Possible. Airjet nozzle size : 1.3mm – Heberline Swis – P143. that factory is commissioning company just only for tezturizing. Recently producing DTY 50D~150D, capacity: 3~6kg/cone compound yarns.

Power: 380V, 50Hz. Condition running and very good.

AA10/061025E/YA-R/M/BY/

Lezzeni Double Twister

Quantity: 6, Year: 1997-2003, mod.TBR LA 2 x 1, Take up 128 spindles, Ring dia.135 mm., Gauge 240 mm., Input 256 spindles upper deck.Machines running.

AA05/021025/AQ/

Schlafhorst Open End Autocoro SE10 & SE11

Quantity: 4

1x Schlafhorst Open End Autocoro AC0312 SE-11 SRZ

Year: 2001, 288 Spindles; lnformator; Opening roller B174; Rotor T240 BD; Twin disc Laser; Navel magnetic KSK4; Corolab clearers; Waxer; 2 Yarn piecers (ASW); 1 Shuttle; Exit package 6″; Voltage 380.3.5O hz.

1x Schlafhorst Open End Autocoro C0288 SE-10 SRZw/ PINTER SLUBING

(This machine can work either producing normal count or count with slubs (thin and tick points))

Year: 1998, 288 Spindles; lnformator; Opening roller B174; Rotor T240 BD; Twin disc with reflector; Navel magnetic K4; PINTER SLUBING; Corolab clearers; Waxer; 2 Yarn piecers; 1 Shuttle; 1 Cone changer; Exit package 6″; Voltage 380.3.5O hz.

1x Schlafhorst Open End Autocoro AC0288 SE-10 SRZ

Year: 1998, 288 Spindles; lnformator; Opening roller B174; Rotor T231 BD; Twin disc Laser; Navel magnetic KSS; Corolab clearers; Waxer; 2 Yarn piecers; 2 Magazine; 2 Cone changer; Exit package 6″; Voltage 380.3.5O hz.

1x Schlafhorst Open End Autocoro AC0288 SE-10 SRZ

Year: 1998, 288 Spindles; lnformator; Opening roller B174; Rotor T240 BD; Twin disc with reflector; Navel magnetic KSK4; Corolab clearers; Waxer; 2 Yarn piecers; 1 Shuttle; 1 Cone changer; Exit package 6″; Voltage 380.3.5O hz.

CONDITIONS: Still running on mill floor

SPARE PARTS: Available (gears, rotors, belts, etc…)

AH27/031025D/ACC-AC/F/

Barmag EFK Texturizing

Quantity: 1, Year: 2010, 240 spindles, JETS are Chinese brand. Original INVERTER SCHNEIDER brand. RANGE OF DENIERS: 50-300d running, Made in China, Running with yarn now.

AB46/011025/

Schlafhorst OPEN END Autocoro 480

Quantity: 1, Year : 2011, 192 spls, Corolab XQ, 2 peicers,, 33mm, B 174DN

AA02/011025/BY/

Trutzschler Blowroom Cotton Line

1x TRUTZSCHLER BALE OPENER, Type BO-A, Year 2017.

1x TRUTZSCHLER MULTIFUNCTION SEPERATOR, Type SP-MF, Year 2017.

1x TRUTZSCHLER CONDENSER, Type BR-COI, Year 2012.

1x TRUTZSCHLER CLEANER, Type CLP, Year 2012.

1x TRUTZSCHLER FAN, Type TV 425, Year 1996.

1x TRUTZSCHLER MIXER, Type MPM8, Year 1996, 8 Cells.

1x TRUTZSCHLER CONDENSER, Type BR-COI, Year 2012.

1x TRUTZSCHLER FEEDER, Type FD-T 1600, Year 2012.

1x TRUTZSCHLER FINE OPENER, Type CLC 3, Year 2012, 3 Opening Rollers.

1x TRUTZSCHLER CONDENSER, Type BR-COI, Year 2017.

1x TRUTZSCHLER FEEDER, Type FDS, Year 2017.

1x TRUTZSCHLER FOREIGN FIBRE DETECTOR, Type TS-T5, Year 2017.

1x TRUTZSCHLER FAN, Type BR-FD425, Year 2017.

1x TRUTZSCHLER CONDENSER, Type BR-COI, Year 2017.

1x TRUTZSCHLER FEEDER, Type FDS, Year 2017.

1x TRUTZSCHLER MULTIFUNCTION SEPERATOR, Type SP-FPU, Year 2017.

AE30/240925D/AORI-PI/F/

Rieter Blowroom & Carding

BRAND NEW IN BOXES, Year of make: 2023

1X Rieter A12 unifloc

1X Rieter B15

2X Rieter B76

4X Rieter A21

12X Rieter C80 carding machines

For sale as a complete LOT.

AB55/240125/BD/

Complete Saurer Schlafhorst Open End Spinning Plant with 1728 Rotors

This factory is currently running , spinning all cotton, both recycled and virgin cotton.

Production offered:

100% Cotton OE Yarn Virgin Cotton Ne 6/1 – 30/1.

100% Cotton OE Yarn recycled Blend Ne 3.5/1 – 8.5/1.

Polyester/cotton 50/50%, 65/35% + 35/65% Ne 6/1

COTTON BLOWROOMS:

Bale Opener BO-A Blendomat , 2017

Multi function separator SP-MF, 2017

Condenser – Feeder BR-COI, 2012

Cotton Cleanere CLP, 2012

Fan Tv425

Multimixer 8 chamber MPM8

Condenser – Feeder BR-COI, 2012

Opener FD-T 1600, 2012

Cleaner CLC3, 2012

2-way distributor BR 2W, 2017

LINE-A:

Condenser feeder BR-COI, 2017

Opener FDS, 2017

Foreign particle separator Ts-T5, 2017

Fan BR-FD425, 2017

2 way distributor BR 2W , 2017

Condenser feeder BR-COI, 2017

Fine Opener FDS , 2017

Foreign particle separator SP-FPU

LINE-B:

Automatic bale opener BDT 019

Condenser feeder BR-COI, 2017

Condener LVSA

Condenser LVSA

Bale OPener , 2 chambers BOAL

Metal detector SCFB

Multimixer 6 chambers MX-U6, 2017

Securomat Foreign particle separator , SCFO(SP-F)

Fan, TV425

Air Separator BR-ASI, 2017

Recycling separator ASTA

Condenser LVSA

Pre- cleaner BEW

2 Roller cleaner WST2

POLYESTER LINE:

Bale Opener BDT019

Waste Opener SAS (BO-R)

Condenser LVSA

Bale Opener BOA

Opener TFV1

2 way distributor BR 2W, 2017

Condenser feeder BR-COI, 2017

Fine Opener FDS , 2017

Opener Feeder BL-HF, 2017

Weigh Pan BL-WP, 2017

Opener Feeder BL-HF, 2017

Weigh Pan BL-WP, 2017

Tuft blender BL-TO, 2017

2 way distributor BR-2W, 2017

Line 1:

Multi mixer , 10 chambers, MX-U10 , 2017

Condenser feeder BR-COI, 2017

Fine Opener FDS , 2017

Fan TV425, 2017

Air Separator, BR-ASI, 2017

Line 2:

Multi mixer , 10 chambers, MX-U10 , 2017

Condenser feeder BR-COI, 2017

Fine Opener FDS , 2017

Fan TV425, 2017

Air Separator, BR-ASI, 2017

Portal Bale Opener BOP, 2017

Fan BR-F500, 2017

Line 3:

Pre-mixer support table BO-E , 2017

Condenser feeder BR-COI, 2017

Opener TO-T1

Foreign particle separator , SP-FPU

Waste presses

CARDS & INTEGRAL DRAW FRAMES:

3x Trutzschler TC11 IDF-R Cards, 2013/17

Integral Draw Frames

Can changers

8x Trutzschler TC15 IDF-2R Cards, 2017

Integral Draw Frames

Can changers

Rectangular cans , contents approx. 23kg each

OPEN END SPINNING FRAMES:

3x SAURER SCHLAFHORST OPEN END SPINNING FRAMES, Type ACO-9, 216 rotors, 1 Doffer cleaning unit per side , 2018

1x SAURER SCHLAFHORST OPEN END SPINNING FRAME, Type ACO-8, 216 rotors, 2 Doffer cleaning units per side, 2012

4x SAURER SCHLAFHORST OPEN END SPINNING FRAMES, Type ACO-8, 216 rotors, 1 Doffer cleaning unit per side, 2014/15

2x SCHLAFHORST OPEN END SPINNING FRAMES, Type ACO 288 with SE11 Spinboxes, 1 Doffer cleaning unit per side, 1997/2001

Waste presses

Overhead package transfer system to packing area.

Engineers for supervision of installation available.

Line is in production.

AA02/011025/AN/

Trutzschler Carding & Saurer Open End Machines

3x TRUETZSCHLER CARDS Type TC 11

Year: 2013(2), 2017 (1), with Drawing Head, Type IDF-R, with autoleveller, with Can changer, Type CC-R, with TRUETZSCHLER CORNERED CARD Cans, Year of manufacture 2010 – 2017, Suitable for TC7 to TC19 cards, Dimensions 920mm x 220mm x 120mm

8x TRUETZSCHLER CARDS Type TC 15

Year: 2017, with Drawing Head, Type IDF-R-II, with Can changer, Type CC-R, with auto leveller, TRUETZSCHLER CORNERED CARD Cans, Year of manufacture 2010 – 2017

Suitable for TC7 to TC19 cards, Dimensions 920mm x 220mm x 120mm.

5x SAURER OPEN END SPINNING MACHINES Type ACO 8

Year 2012(1),2014(2), 2015(2), 216 Pos. Rotor dia. 33 mm, Spin box SE 20, Corolab Yarn Clearers, Type XF, with Foreign Fibre detection, Face Plate Type 31, Opening Rollers Type B 174 DN, Informator OSC with Touchscreen and USB, Conometer, Automatic Package Lift with, Neuenhauser Cone Transport, DIGI Piecing, (1) 4 Doffers, (4) 2 Doffers, Multilot 3 System.

3x SAURER OPEN END SPINNING MACHINES Type ACO 9

Year 2018, 216 Pos., Rotor dia. 31 mm, Corolab Yarn Clearers, Type XF, with Foreign Fibre detection, Face Plate Type 31, Opening Rollers Type B 174 DN, Informator OSC with Touchscreen and USB, Conometer, Automatic Package Lift with, Neuenhauser Cone Transport, DIGI Piecing, 2 Doffers, Multilot 3 System.

1x SAURER OPEN END SPINNING MACHINE Type ACO 8

Year 2011, Upgraded in 2017 to AC10 Software, With 10% energy savings, 408 Pos., Rotor dia. 33 mm, Rotor type TB 633 B, Spin box SE 20, Corolab Yarn Clearers, Type XF, Face Plate Type 31, Opening Rollers Type B 174 DN, Navel Type Spirit R, Informator OSC with Touchscreen and USB, Conometer, Traverse Motion System (Tooth Belt), Automatic Package Lift, 4 Doffers, DIGI Piecing, Waxing device 75 mm x 45 mm, Green Torque Stop, Angle of Wind 26-44 deg, Cradle Pressure 0-60 N, with Multilot 3 & Sampling System.

AA10/300925E/RP-R/M/

Savio Cone to Cone Winder

Quantity: 1, Year: 2003, mod.ORION L, 48 heads, Delivery 6″ cylindrical, Loepfe TK830N clearers, Acquasplicer Mesdan 492/4E, blower, cone autom.change, without waxer.

AA10/300925E/CP-R/M/

Cognetex Ring Spinning Frames

Quantity: 3 , Year: 1986, mod. FTC-7L , 1024 spindles, tube 280 mm, closed draft SKF PK-1601, ring dia.51 mm, gauge 75 mm, 1 Magitex vacum cleaner

AA10/300925E/RP-R/M/

Cognetex Ring Spinning Frames

Quantity: 5, Year: 1990, mod. FTG-7L, 672 spindles, gauge 75 mm, ring dia. 51 mm, tubes 260 mm, draft SKF for short fibers, autodoffer. Blower

AD81/290925E/AL-A/F/

Trutzschler DK 903 Carding Machine

Quantity: 20 , Year: 2001, Chute Feed Type DFK, Manual, Can Dia. 1000/ 1200

AI48/290925/

Dref 2

Quantity: 1, Year: 1988, Status Fully recontinued, 12 spindles combined, Status Running, New electronic equipment, Brand New motors, converter, Test Run offered, Online inspection offered.

AE02/300925E/OCY.L-RY.L/M/

Oerlikon-Barmag FDY Draw Spinning Machine

Quantity: 1, Year: 2017, Type SDM60, 24 positions (8 yarn ends each), suitable for mulifilament FDY and POY yarn

AF45/300925E/PR-Y/C/

Saurer Carpet Cabler

Quantity: 1, Year : 2015 / Start up 2016, Type 05-0-C

Machine ihas less workinghours and is like new, Type 8.02, Number of spindles: 40

Output: 10“ (254mm) cylindric, max diameter 400mm, spindelpotdiameter 285mm, spindelpot high 300mm, Fabrics: Acryl, glass fibers, copper

AA14/290925D/PC-T/M/

FEHRER DREF SPINNING MACHINES

QUANTITY: 2, YEAR: 1981.

24 SPINDLES TOTAL

12 SPINDLES X 2 MACHINES FOR 24 TOTAL SPINDLES

12 SPINDLES CURRENTLY IN PRODUCTION (SPINNING UNITS, CARDING DRUMS AND SUCTION NOZZLES ARE IN GREAT WORKING CONDITION AND WELL MAINTAINED AS SEEN IN PICTURES)

12 SPINDLES FOR SPARE PARTS: MISSING SPINNING HEADS ON 3 OR 4, CAN BE USED FOR SPARE PARTS OR MIGHT BE RECONDITIONED TO THE ORIGINAL SPECIFICATION

INCLUDES:

ALL FUNCTIONAL PLC CONTROL PANELS

AC INVERTERS – REDUCE SPEED FOR INTAKE MOTORS AND OUTPUT

AC TRANSFORMER – 220 VOLTS (INTAKE) TO 440 VOLTS (MACHINES)

THE MACHINE HAS AN EXTRACTION AIR FACILITY.

TECHNICAL DOCUMENTATION (MANUAL, ETC.) IS AVAILABLE FOR THE MACHINES.

IN PERFECT WORKING CONDITION, CURRENTLY IN PRODUCTION.

AB45/220925E/YC-AI/F/BY/

Fehrer Dref 2/94

Quantity: 1, Year: 1994, 6 positions, Electrical panel, Working condition.

AI70/260925D/YC-AI/F/BQ/

Savio TFO

Quantity: 1, Year: 2020, Model – Sirius, Pots – 192 (Extendible upto 360 pots)

Feed Traverse – 8″, Pot – 190 mm, Delivery – 6″, Dual Motor, Heavy Duty

AA02/250925E/ACCP-LI/F/

Saurer Open End

Quantity: 4

3x Year: 2018, Type ACO 9, 216 Pos., Rotor dia. 31 mm, Corolab Yarn Clearers, Type XF, With Foreign Fibre detection, Face Plate Type 31, Opening Rollers Type B 174 DN, Informator OSC with Touchscreen and USB, Conometer, Automatic Package Lift with Neuenhauser Cone Transport, DIGI Piecing, 2 Doffer, Multilot 3 System.

1x Year: 2018, Type ACO 9, Model E3, Individual Spindle Drive, Piecing Per Spindle, Multi Count Possible, 168 Positions, Corolab, Waxing Device

Tube Take Up, Two Piecers, 46 mm Rotors, B 06 DS DN Combing Roll, Electrics: 575/60.

AG41/250925E/RR-R/M/BT/

Seydel 870 Breaker

Quantity: 1, Year: 1994, Tow, Area Needed(m): 15L*3W*4H, Average production: 7000Kg, Feeding: Tow, Out put: 1Can. Machines are in production, in perfect condition.

AG41/250925/BT/

Complete Preparation, Spinning, Finishing Line

Preparation Line:

AG41/040825E/RR-R/M/

1x Seydel 870 (Breaker) France, Year: 1994, Tow, Area Needed(m): 15L*3W*4H, Average production: 7000Kg, Feeding: Tow, Out put: 1Can.

AG41/040825E/CP-R/M/

1x Schlumberger RL10 Rebreaker France, Year: 1991, Tops Product, Area Needed(m): 12L*4.5W*4H, Average production: 5500Kg, Feeding: 8-14 feeder, Output: Tops .

AG41/040825E/O-A/M/

1x Schlumberger Gc12 France, Year: 1987, Mixing Colors, Area Needed(m): 12L*4.5W, Average production: 3500Kg, Feeding: 10 feeder, Output: 1 Can 120cm*70cm.

AG41/040825E/O-A/M/

1x Schlumberger Gc12 France, Year: 1987, Line (A) 1ST Area Needed(m): 12L*4.5W, Average production: 3500Kg, Feeding: 8 feeder, Output: 1 Can, 120cm*100cm.

AG41/040825E/O-A/M/

1x Schlumberger Gc12 France, Year: 1986, Line (A) FinalArea Needed(m): 10.5L*4W, Average production: 3500Kg, Feeding: 8 feeder, Output: 2Can, 110cm*70cm.

AG41/040825E/O-A/M/

1x Schlumberger Gc12 France, Year: 1980, Line (B) 1ST, Area Needed(m): 10L*3.5W, Average production: 3500Kg, Feeding: 8 feeder, Output: 1 Can, 120Cm*100cm.

AG41/040825E/O-A/M/

1x Schlumberger Gc12 France, Year: 1980, Line (B) Final, Area Needed(m): 8L*3W, Average production: 3500Kg, Feeding: 8 feeder, Output: 2Can, 120cm*70cm.

AG41/040825E/AAL-AI/M/

1x Schlumberger Gc40 Autoleveller France, Year: RE2021, Middle Stage, Area Needed(m): 10.5L*4.5W, Average production: 8000Kg, Feeding: 8 feeder, Output: 1 Can, 120Cm*70cm.

AG41/040825E/CP-R/M/

1x Schlumberger FMV30 France, Year: 1986, False Twist, Area Needed(m): 12L*7W, Average production: 3200Kg, 32/16 spindles, Output: double, Gauge: 420mm.

AG41/040825E/CY-C/M/

1x Schlumberger BM14 France, Year: 1987, Low Twist, Area Needed(m): 15L*7W, Average production: 3200Kg, 64 spindles, Output: single, Gauge: 140mm.

Spinning Line:

AG41/040825E/S-A/M/

1x Continua N.5 Spain, Year: 1980, 416 Spindles, Ring Dia. 60, Spindle centre 60, Area Needed(m): 21L*1.5W +1.5M W Each side, Average production: 500Kg 2Nm-35Nm.

AG41/040825E/AA-A/M/

8x Zinser 421E Germany, Year: 1996, Area Needed(m): 23L*1.5W +1.5M W Each side, Average production: 350Kg-400Kg (Total:2800Kg-3200Kg), 10Nm-85Nm. Spindle centre 82.5.

No.1- Spindles: 480, Ring dia: 56.

No.2- Spindles: 460, Ring dia: 56.

No.3- Spindles: 456, Ring dia: 54.

No.4- Spindles: 484, Ring dia: 52.

No.5- Spindles: 484, Ring dia: 52.

No.6- Spindles: 484, Ring dia: 52.

No.7- Spindles: 484, Ring dia: 54.

No.8- Spindles: 456, Ring dia: 54.

Finishing Line:

AG41/040825E/OO-O/M/

1x Winding Schlafhorst X5 Germany, Year: 2013, Spindles: 50/5section, Delivery 4’20, Area Needed(m): 19.5L*2.5W +2m Each side, Average production: 2500Kg, 3 Partitions Clip cone. Bobin exit 4”20. All machines are manual feeding.

AG41/040825E/OO-O/M/

1x Winding Schlafhorst X6 Germany, Year: 2016, Spindles: 50/5section, Delivery 4’20, Area Needed(m): 19.5L*2.5W, Average production: 2500Kg, 2 Partitions Clip cone. Bobin exit 4”20. All machines are manual feeding.

AG41/040825E/SY-S/M/

1x Compact Twister Volkmann Germany, Year: 2013, Spindles: 162, Guage: 230mm, Delivery 4’20, Area Needed(m): 22.5L*1W +2m Each side, Average production: 900 Kg, 10Nm-85Nm. double feeding, Intake small cone, Output 4”20. Twin pack, Feeding with 2 4’2 cone, Deliver 1 twisted.

AG41/040825E/S-A/M/

4x Twister Volkmann Germany, Year: 1968, Spindles: 120, Guage: 245 mm, Delivery 4’20, Area Needed(m): 18L*1.5W +2m Eachside, Average production: 500 Kg (Total:2000Kg), 5Nm-45-Nm. double feeding, Intake small cone, Output 4”20.

AG41/040825E/S-A/M/

3x Superba + Winding Shlafhorst 138 France-WP/Fu, Year: 1994, Delivery 4’20, Area Needed(m): Total 13L*7.5W, Average production: 500Kg (Total:1500Kg).

AG41/040825E/S-A/M/

4x Superba + Winding Shlafhorst 138 France-WP/Fu, Year: 1994, Delivery 4’20, Area Needed(m): Total 16L*7.5W, Average production: 500Kg (Total:2000Kg).

AG41/040825E/AA-A/M/

1x Superba + Winder France-WP/Fu, Year: 2004, Delivery 4’20, Area Needed(m): 3.5L*2W, Average production: 500Kg.

Machines are in production.

All machines are in perfect condition.

We have big stock spareparts for all machines.

Till next november.

AA02/250925/BB/

RIETER AIRJET SPINNING MACHINES

Quantity: 6

YEAR: 2023 (NEVER USED) WITH 120-200 POS.

AA02/270825E/YSL-CI/F/

3x RIETER AIRJET SPINNING MACHINES FOR VISCOSE

Type J26

Year 2023 (BRAND NEW - NEVER USED)

200 Pos.

Can Height 1070 mm

6 Robots

Cylindrical packages

Total Yarn Count Ne20-40

Delivery Speed max. 500 m/min.

Z Twist Yarn

Package dimensions cylindrical up to 300 mm dia.

Package weight up to 4,5 kg

Tube loader capacity max. 412 tubes

Individual driven waxing device

Spinning Unit gauge 260 mm

Individual drives for each Position

Independent machine sides

Automated piecing preparation

Yarn Quality sensor, Type Q10A

Spider Web Interface

Machine Length 35 m

Machine Width 3,1 m (4,85m with open robot doors)

Machine Height 3,3 m (ceiling height 3,6 m required)

AA02/250825E/CSI-AL/F/

3x RIETER AIRJET SPINNING MACHINES FOR COTTON

Type J26

Year 2023 (BRAND NEW -NEVER USED)

120 Pos.

Can Height 1070 mm

4 Robots

Cylindrical packages

Total Yarn Count Ne 20-40

Delivery Speed max. 500 m/min.

Z Twist Yarn

Package dimensions cylindrical up to 300 mm dia.

Package weight up to 4,5 kg

Tube loader capacity max. 412 tubes

Individual driven waxing device

Spinning Unit gauge 260 mm

Individual drives for each Position

Independent machine sides

Automated piecing preparation

Yarn Quality sensor, Type Q20AF with FFD (Foreign fibre)

Spider Web Interface

Machine Length 23,5 m

Machine Width 3,1 m (4,85m with open robot doors)

Machine Height 3,3 m (ceiling height 3,6 m required)

AI08/240925D/PA-T/F/BA/

NSC GC30 Gill Box

Year: 2012, The machine comes standard with an autoleveller. The delivery form is a silver can coller (ball-shaped). Creel Configuration: The creel is a 2 x 3 ends design. This model is currently in production.

AB45/250925E/YL-L/F/AQ/

PA-FA Fancy Yarn

Quantity: 1, Year: 2005, Ring Spinning and Fancy , mod. EXPO 80, 48 spindles, Suitable to produce effect yarns in medium / coarse counts , in new combinations of colors in a wide range , for both regular and or fancy yarns, Double Sampre draft ( machine can be feeding by one or two slivers ), electronic programmer PC to set fancy effects and video data processing, feeding by external feeding creel ( by slivers from Flyer or Finisher bobbins or by tapers from cans ), ring diameter 140 mm. delivery on tubes h. 600 mm. Machine will be completely refurbished before delivery, Condition: dismantled.

AA10/230925/

SCHLAFHORST Cone winder AUTOCONER 5 149

Quantity: 1, Year: 2008, 24 heads, delivery 6”, 4°20, Loepfe Zenith C clearers, thermosplicer, waxer, 1 trolley doffer, autom. feeder, tube 265 mm

AA10/230925/

NSC GN5 Worsted set

Composed of:

1st Gill box, feeding 12 bobbins/cans, delivery 1 can 700×1000 mm, 1 sliver, manual

2nd Gill box, autoleveller, feeding 10 cans, delivery 1 can 700 x1000 mm, 1 sliver, manual change

3rd Gill box mod.GN5, feeding 10 cans, delivery 1 can 700 x1000 mm, 2 slivers, manual change

AA10/230925/

Savio Orion E Cone Winder

Quantity: 1, Year: 2003, 38 heads, Delivery 6″, 4°20, 1 autom. feeder, autodoffing, Loepfe Yarn Master TK930S, splicer Mesdan 594, waxer.

AC94/230925D/LAL-RI/F/AT/

Oerlikon Barmag POY Extrusion Line for Polyester

Year: 2011

80 thread lines

(1) Horizontal Extruder (e-save) type 9E10, 90mm ø

(1) Continuous Polymer Filter (60 – 300 kg/hour)

(2) Spinning Heads type SP87D(DIO), 2 pos per module

(10) PC Spin packs/position

(8) Spinning Pump drive (1 extra)

(10) Spinning Pumps type GH30XK Planetary

(4) Eco Quench Radial Inflow system (suitable for micro denier)

(1) Spin Finish Supply system inc. 10 x Spin Finish pumps type GFD1XA-50

(1) Heat transfer installation inc Vaporization vessel of heating cap. 59.28kw

(1) Control panels, inverters, etc.

(8) Take up Winders type WINGS POY 40T-1500 with 10 positions each

(1) Spare winder

Laboratories equipmets are available at extra cost. (Some of the lab pieces have been sold.)

Note:

The line uses PET chips fed into extruders. It does not feed from polymer.

PRODUCTION:

4.2 tons/day – 76/72

6.1 tons/day – 100/72

8.2 tons/day – 150/144

POWER IN K/W

Nominal Power/Operation power

Dryer: 60/43.5

Extruder/Spinning head/Vaporisation vessel: 90/41.1

Wings Winders: 20/15.2

Evo Quench (temp/relative humidity/quality air filtrate):20/10

Original Oerlikon specification sheet are on the LINK which gives more details on the line including scope of supply.

Plant closed Nov. 2023. All equipment standing on the factory floor.