AC94/030324D/LAL-RI/F/AT/

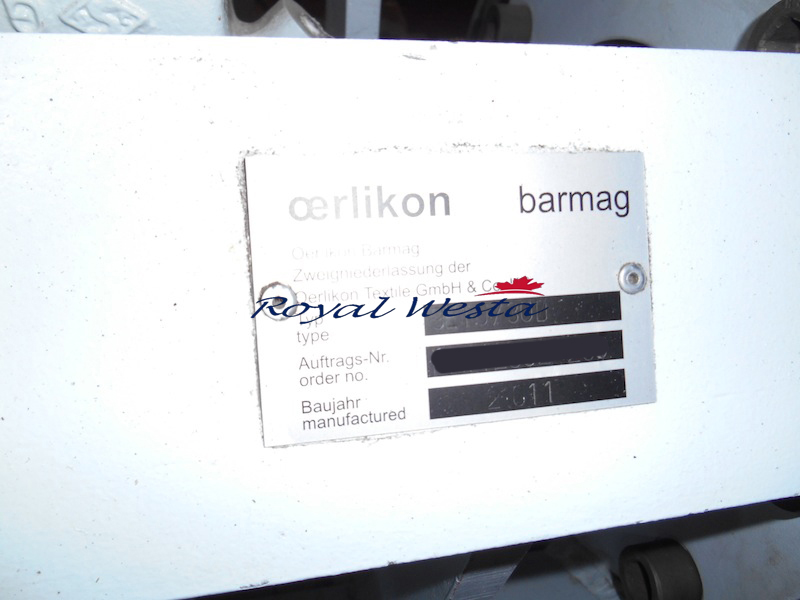

Oerlikon Barmag POY Extrusion Line for Polyester

Year: 2011

80 thread lines

(1) Horizontal Extruder (e-save) type 9E10, 90mm ø

(1) Continuous Polymer Filter (60 – 300 kg/hour)

(2) Spinning Heads type SP87D(DIO), 2 pos per module

(10) PC Spin packs/position

(8) Spinning Pump drive (1 extra)

(10) Spinning Pumps type GH30XK Planetary

(4) Eco Quench Radial Inflow system (suitable for micro denier)

(1) Spin Finish Supply system inc. 10 x Spin Finish pumps type GFD1XA-50

(1) Heat transfer installation inc Vaporization vessel of heating cap. 59.28kw

(1) Control panels, inverters, etc.

(8) Take up Winders type WINGS POY 40T-1500 with 10 positions each

(1) Spare winder

Laboratories equipmets are available at extra cost. (Some of the lab pieces have been sold.)

Note:

The line uses PET chips fed into extruders. It does not feed from polymer.

PRODUCTION:

4.2 tons/day - 76/72

6.1 tons/day – 100/72

8.2 tons/day - 150/144

POWER IN K/W

Nominal Power/Operation power

Dryer: 60/43.5

Extruder/Spinning head/Vaporisation vessel: 90/41.1

Wings Winders: 20/15.2

Evo Quench (temp/relative humidity/quality air filtrate):20/10