AI56/100625/

Rieter RSB 951 Draw Frame

Year : 1996/1997, 18 İnch, Can Dia : 45/107, Automatic bucket extraction

AI56/100625/

Schlafhorst SE11 Open End

QUANTITY: 1, YEAR: 2001, 288 Spindle, Double Robots, Rotor Dia :* 31*, Corolab available, Combing Rolls : B174 DN

AF08/090625/CM/

SSM Air Covering DP-C

Quantity: 32, Year: 1999-2002, Per section of 5 spindles, per set of 30 spindles. Per spindles was independent. Doffing from back side. Power installation of 380 V 60 Hz. The machines have good condition. Some machine still running and some machine stopped in the factory floor, can be separated for sale.

AE56/030625/

Muratec Vortex 870

Quantity: 2, Year 2016, 96 spindle, G2Z splicer, With 4 splicer & 1 doffing trolley, MSC cleaner, 95% new machine(The working hours are only 13,000 hours)

AA10/030625/

SCHLAFHORST Open End

Quanttity: 1, Year: 2001 , model 312, Type SE 11,, 288 rotors, Dia 40 or 36, Waxing, B174, Corolab, 2 robots, 6″ cylindrical

AB46/090625/

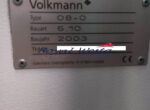

Volkmann VTS-07 Twister

Quantity: 4, Year: 1987, 168 Spindles, 8″ outer pot, 7.5″ inner pot, 1 TFO (Half Cone, Half Dyetube), 1 TFO Dyetube, 2 TFO Straight tube

AB46/090625/

Volkmann VTS-07 Twister

Quantity: 3, Year: 2×1980, 1×1989, TFO for Cone, 156 Spindles, 8″ outer pot, 7.5 inner pot

AA10/030625E/RP-R/M/BY/

Gaudino Woollen Ring Spinning Frames

Quantity: 1, Year: 1980 about, mod.FST , 196 spindles, ring dia.90 mm., tube 450 mm., 1 autodoffing.

AA10/030625E/YR-R/M/

GAUDINO Woollen Ringspinning Frame

Quantity: 1 , Year: 1996, mod. FB type BIELLA , 228 spindles, ring dia.90 mm., gauge 115 mm., tube 400 mm.

AA10/040625/

ZINSER Worsted Spinning Frame First Class Condition

Quantity: 1, Year: 1997, Type RM 450, 384 spindles, Ring diameter 50 mm, pitch 75 mm, Drafting SKF PK6000, Tubes 260 mm, equipped for Lycra

AA02/030625/

Saurer Schlafhorst Open End

Quantity: 1, Year: 2018, Type ACO 9, Model E3, Individual Spindle Drive, Piecing Per Spindle, Multi Count Possible, 168 Positions, Corolab, Waxing Device

Tube Take Up, Two Piecers, 46 mm Rotors, B 06 DS DN Combing Roll, Electrics: 575/60.

AA02/030625/

Saurer Schlafhorst Open End

Quantity: 2, Year of Manufacture 2023 ( Still in Original Packing- Un Opened), Model ACO.1, 480 Rotors, Cylindrical Tuber Take up, SE20 Spin Boxes with individual drive technology, E Drive Technology (e3), Synchronized Digi Piecing-Up to 24 piecing processes simultaneously, 4 Automatic Doffer, Multi Lot 2 with seamless lot change, Corolab XQ Yarn Clearers, Belcoro Torq stop, Waxing, Overall Length 60,790 mm, Width 1,547 mm, Air Dryer and Filter for improved air from Air Compressor.

AA02/030625/

Saurer Open End

Quantity: 5, Year: 2012(1),2014(2), 2015(2), Type ACO 8, 216 Pos., Rotor dia. 33 mm, Spin box SE 20, Corolab Yarn Clearers, Type XF, With Foreign Fibre detection, Face Plate Type 31, Opening Rollers Type B 174 DN, Informator OSC with Touchscreen and USB, Conometer, Automatic Package Lift with Neuenhauser Cone Transport, DIGI Piecing, (1) 4 Doffers, (4) 2 Doffers, Multilot 3 System.

AA02/030625/

Murata Vortex Air Jet Spinning Frames

Quantity: 5, Model 870.III, VOS III Computer Management System, Year: 2016-72 position (1) / 2016-96 position (1) / 2017-96 position (3), MSC-F yarn clearers with Foreign Fiber Detection, 6 Air Splicers Model 87-C with G2Z Prisms, 1 Automatic Doffer Modfel 87D, Cone Take up – Cone Angle 5 deg 57’, With Waxing, With Polymaster, Power Supply 380 Volts 50 Hertz.

AE21/040625/

Trutzschler Axiflow & Marzoli Opener

2x Trutzschler Axiflow

1x Marzoli Opener model B36, year 2000

AA02/040625/

Trutzschler Carding

1x TRUETZSCHLER CARD

Model DK 903, Year 2002, Stationary Flats, Aluminum Flat Bars, Sliver air doff to bale press.

10x TRUETZSCHLER CARDS

Model DK 903, With Chute Feed, Year (1) 1999 – (4) 2001 – (5) 2002, KH 600 Coilers, 3 Position Automatic Can Changer, 30 x 48” Can, Stationary Flats, Aluminum Flats, Card Commander.

29x TRUETZSCHLER CARDS

Type DK 903, 3 Position Automatic Can Changer, 40 x 60 Can Size with castors, Aluminum Flats, Triple Licker In, Year 1999.

4x TRUETZSCHLER CARDS

Model TC 7, With DKF Direct Feed, Year 2013, 30″ Coiler Type CCA/3 Positions, Stationary Flats, Aluminum Flats, Truetzschler Chute.

3x TRUETZSCHLER CARDS

Type TC 11, Year 2013(2), 2017 (1), With Drawing Head, Type IDF-R, With Can changer, Type CC-R, for cornered cans.

8x TRUETZSCHLER CARDS

Type TC 15, Year 2017, With Drawing Head, Type IDF-R-II, With Can changer, Type CC-R, For cornered cans.

AA03/061224E/AA-C/F/CF/

NSC GN6 Gillbox

Quantity: 1, Year: 1981, Feeding: 12 bobbins, alternative cans + 4 bobbins, RMC-drawing device for 4 bobbins, oiling device , Delivery: 1 sliver in 1 can dia. 1000 x 1200 mm, Automatic can changer.

AA10/040625E/TL-L/M/

Gaudino Woollen Ring Spinning

Quantity: 2, Year: 2001, Type FST/350 SELFSTIRO, 264 spindles, Ring 75 mm, Tubes de 350 mm.

AB65/260724/BG/

Rieter Open End R-40

Quantity: 2, Year: 2006 , Rotors 280, 2 Robot, Diam . 40 mm, Roller Type OS-21, Clearer Uster Quantum 2, Waxing, Conicity : 2º

AA05/020625/

O.RIELO Complete Wool Scouring & Drying Line

BRAND: O.RIELO MADE IN ARGENTINA

COMPOSITION OF THE LINE:

START OF THE RAW WOOL PROCESSING LINE: SCOURING, WASHING, AND DRYING.

• PRIMARY FEEDER FOR GREASY WOOL:

Equipped with horizontal and vertical slatted conveyors fitted with pinned rollers for handling raw fiber.

Dimensions: 4300 mm length x 2200 mm width.

• OPENING AND DUST REMOVAL UNIT:

Featuring a wool opener and dedusting system with aeration and mechanical beating.

Composed of one primary drum: 1500 mm diameter x 2200 mm width.

Plus five auxiliary cleaning drums: each 1000 mm dian1eter.

Total: 6 drums for efficient wool opening and impurity separation.

• SECOND FEED CONVEYOR PRE-SCOURING FEEDER:

Delivering opened wool to the first scouring bowl.

Dimensions: 3000 mm length x 2200 mm width.

Includes horizontal conveyor and vertically pinned rollers for fiber advancement.

• SCOURING SECTION:

Consisting of 6 stainless steel scouring bowls:

Each bowl: 7000 m m long x 1600 mm wide x 550 m m scouring depth.

Equipped with internal wool transport forks (drag arms) – 11 per bowl – for progressive fiber transfer between bowls.

• ROLLER SQUEEZER UNIT:

Integrated at the exit of each bowl: 300 mm diameter x 1300 mm width.

Pneumatically actuated system.

Includes top roller made of ebonite rubber and bottom roller in granulated stainless steel for high-efficiency dewatering.

• INTERMEDIATE DEWATERING MODULE:

Prior to the dryer inlet:

Features 5 stainless steel squeeze rollers with pneumatic tensioning, facilitating moisture reduction and continuous transfer.

• THIRD FEEDER – WOOL OPENER AND FEEDING UNIT TO DRYER:

Ensuring uniform and unclumped wool feed into the thermal drying chamber.

• HOT AIR DRYING OVEN:

Dimensions: 3000 mm width x 2500 mm length.

Designed for uniform thermal airflow to achieve consistent fiber moisture levels.

• FIBER EXTRACTION AND CONVEYING SYSTEM:

Employing high efficiency centrifugal fans and ducting to transfer dry wool fibers, pneumatically to automated baling presses, completing the clean wool processing cycle.

AA10/030625E/RR-R/F/BY/

Gaudino Woollen Ring Spinning Frames

Quantity: 3, Year: 1980 about, mod.FST, 204 spindles, Without autodoffing, tube 450 mm., ring dia.90 mm.

AA94/160525E/YS.L-Y.L/F/

HOUGET DUESBERG BOSSON AUTOMATIC CARDING SET with 2 Swifts

Quantity: 1, ww. 2200 mm, including:

Scribbler card: weighting Hopper Feeder, Licker-in 320 mm, Breast apparatus Ø 1000 mm, 3 work/strip Ø 215/90 mm, Swift Ø 1270 mm, 4 work/strip Ø 215/100 mm, doffer Ø 1000 mm, Peralta, Band transporter for straight fibre feed.

Finisher card: Lapper, Licker-in Ø 320 mm, Swift Ø 1500 mm, 5 work/strip. Ø 300/100 mm, doffer Ø 1270 mm, double rubber tape condenser 112 good ends, tapes 18,5 mm, endless tape, shallow groove, double winding frame (tandem creel), 1 spare division 24,8 mm 84 good ends, steel wire card clothing.

AE21/080125E/CP-R/F/AY/

Savio Winder ECO PULSARS I DLS

Quantity: 1, Year: 2018

MOD.’ECO PULSARS I DLS'(LINK) COMPLETE OF:

RH headstock, 14 Positions, Interface to link, Feeding tube length 160 mm, Automatic doffer, Individual cone baskets, Individual splicer type: JOINTAIR 8951 (moist splicer) suitable for 100% cotton, MMF, Blends, count range Ne 24 – 100 (prism type 60Z2 – prism cover C6 – Preparators PP23 for Z twist yarns; prism type 60S2-prep. PP24 for S twist yarns), Electronic yarn clearers type LOEPFE YM ZEN IT+ DF (foreign fiber detection), Winding drums 2,5 turns, 152 mm traverse, 94 mm dia., Waxing device with wax finished detection probe, Quick adjusting knob for pre-clearers, Take up packages with 4.20’conicity, Suction pipe with combs.Machine is in warehouse

AC44/300525/

SAVIO Link coner

Quantity: 1, Year: 2021, Model: ECO PULSAR PLUS I DLS, No. of positions: 30, Yarn clearer: USTER QUANTUM 4

AG88/300525/

Schlafhorst Open End BD7

Quantity: 3, Year: 2020, Rotors 480, Rotors/Spindle qty:480, Rotor Type : ASK, Opening roller : OK40, Overhead Cleaner: Yes, Manufacturing years: 2020, Power Supply : 380V/50Hz, Machine Condition : A 90 %New, Machine Status: Running.

AG88/300525/

Trutzschler Blowroom Line with TC10 Carding

Trutzschler Blowroom, Year: 2020

1x Blendomat

1x SP-DX

1x CL-C3

1x Uster Jossi Vision Shield

1x CL-P

1x MX-U

1x AMPE Detection

8x Cards TC10, Year: 2020

Auto Can size XX×1100

No of Licker In : 3

AA05/290525D/TR.L-L/F/BA/

Schlafhorst Autoconer X5

Quantity: 1, Year: 2012, Type BCF, 60 positions, No waxers, Buster Quantum 3 clearers, DZ3 splicers, exit 6″, conicity 5°57′.

AA02/280525/

Truetzschler Fiber Blending and Mixing & Carding Equipment

1 – Truetzschler Electronic Weigh Pan blending line, Year of Manufacture 2008, with (2) precision electronic weigh feeders BL-HW-1600 m& BL-EW-1600 with Wasate hopper feeder type BO-R, 4 meter feed apron and (1) fine opener Type BL-FC-1200

1 – Truetzschler Multi Mixing Bin Type MX1, year of manufacture 2008, 10 cells , 1600mm working width, connected to (1) opener type TO-T1

1 – Truetzschler Multi Mixing Bin Type MX1, year of manufacture 2008, 10 cells , 1600mm working width, connected to (1) 4 roller Cleaner Type CL-C4

1 – Truetzschler feeder hopper, Type FDS-1200 with FDU-1200 hopper, year of manufacture 2012, with Fiber condenser Type BR-CO1

1 – Truetzchler De -Duster type SP-DX, Year of Manufacture 2007

6 – Truetschler Stand alone Condensers, Type LVSA-B year of manufacture 1993

20- Truetschler High Production Cards Type DK903 Auto Can Changer, Year of Manufacture 1999

AA94/280525E/AIC-O/F/AO/

HOUGET DUESBERG BOSSON RING SPINNING FRAMES

Quantity: 2 , Year: 1991, Type : CBP5.114

200 spindles, rings Ø 90 mm, pitch 120 mm, tubes 400 mm, 380 V, cop lifter, pneum. threading. Machines are woollen system.

Requires 1×40 Ctr for each machine

AF08/260525D/CA-S/M/CW/

SSM Soft Core Winder

Quantity: 2, Year: 1996, Model of PW1-W, 48 positions for each sets, Machine still running with fantastic condition.

Bobbin size of D 58 mm x L228 mm, weight of 73 g. plastic material.

AA05/240525/

Rite Doubling Winder

Quantity: 1, Year: 1998, mod. AGR, 80 heads (2 x 40 heads per side), 3 ends couples, manual doffing, individual count meter, Electro Jet blower.

AA05/230525D/YL.L-O/F/AT/

Oerlikon Volkmann Compact 2×1 Twisting VTS08

Quantity: 2, Year: 2003, 192 positions each, Pot dia. 170 mm., exit 6″, conicity 6″, automatic discharge, Magitex blower.

AA05/230525D/AP.L-Y/F/AT/

Fadis Assembly Winder

Quantity: 1, Year: 2003, mod. Sincrotex/B, 42 positions, 3 ends, Delivery 7″.

AA10/210525E/OS-Y/M/BY/

Tematex Breaker MST10

Quantity: 1, Fully refurbished 2020 with new electric panel. 1 can 1000×1200 mm. Complete of Steamer SVZ, 1 set of gears, Upper Creel and structure, accessories. Machine stopped and dismantled.

AE42/200525D/OA-AA/F/BQ/

NSC GC15 R5L10 Rebreaker

Quantity: 1, Year: 1998, With 5 rollers for acrylic tow.

AE30/180525/

Open End Line

Trutzschler Blowroom Line:

Year: 2020

1X Bale Opener BOA-2300

1X Truzschler Multimixer MX-I with CL-C3

1X Truzschler SP-DX

1X Truzschler CL-P

1X Truzschler BR-CO

Trutzschler Cards:

Quantity: 9, Model: TC10-3, Year: 2020, Can Changer: automatic, Can Diam.: 40, Flat Type: Aluminium, Three lickerin.

Saurer Open End BD6:

Quantity: 3, Year: 2016, Model: BD6, 480 ROTORS, 34/54mm rotors, Corolab yarn clearer, Running on mill floor.

Saurer Open End BD7:

Quantity: 3, Year: 2020, Model: BD7, 480 ROTORS, 34/54mm rotors, Corolab yarn clearer, Running on mill.

AA02/200525/BY/

Rieter K48 Compact Ring Spinning Plant

4x TRUETZSCHLER CARDS

Model TC.19.i, Year of Manufacture 2023, Chute Feed, Triple Licker in, Automatic Can Changer, 1000mm x 1200mm can.

2x RIETER BREAKER DRAW FRAMES

Model SB.D50, Year of Manufacture 2022, Power Creel, 4 over 3 draftinG, Auto Can Changer, 1000 mm x 1200mm can, Central Waste collection.

2x RIETER FINISHER DRAW FRAMES

Model RSB.D50, Year of Manufacture 2022, Power creel, 4 over 3 drafting, Auto Leveller, Auto Can changer, 500 mm x 1200mm can

Central waste collection.

1x RIETER OMEGA LAP WINDER

Model E36, Year of Manufacture 2022, Creel for 28 cans, 2 Lap Heads, Doffing to Servo Trolley E17.

5x RIETER LAP SERVO TROLLIES

Model E17, Year of Manufacture 2022.

3x RIETER COMBS

Model E.90, Year of Manufacture 2022, 8 combing heads, Optical Sensors, Rieter Ri-Q combing System, Central Noil Collection.

1x RIETER ROVING FRAME

Model F.40, Year of Manufacture 2022, 216 Positions at 115mm gauge, Creel for 5 Cans, 3 over 3 drafting, Flyer 16 x 6 inches, Auto Doffing, Electrojet overhead Travelling Cleaner.

1x ROVING BOBBIN TRANSPORT SYSTEM

4x RIETER COMPACT SPINNING FRAMES

Model K48. V2, Year of manufacture 2022, 1488 Spindles, 70 mm spindle gauge, Tube Length 190mm, Rieter Drafting, 4 spindle belt drive with Ri-Q Bridge support, Titan N98 Ring Flange, Cradle length 43mm, Ring Diameter 38mm, Automatic doffing, Electrojet overhead Travelling Cleaner.

Linked with:

4x MURATEC LINK WINDERS

Model Q-PRO-EX, Year of Manufacture 2022, 42 Positions, Cone Take up, Waxing, Loepfe Zenit Yarn Clearers, Electrojet overhead Travelling Cleaner.

LOT: Misc. tubes, bobbins, cans, boxes, etc.

AA02/200525/BY/

Murata Vortex Air Jet Spinning Frame

Quantity: 6, Year: 2023, Model MVS, Type Vortex III 870 EX, Vortex High speed spinning system, 96 spindles, VOS.III visual on demand control system, Self spinning system with individual start spinning, Cone take up, MSC Murata Spin Clearers, Waxing, (1) Automatic doffer type 87D EX, (3) High speed Automatic air splicer model 87C EX, Polymaster, Sliver Creel with guides, 4 line draft unit, With front and middle by inverter, 3rd and 4th rolls by individual motor drives, STS Spinning System Stabilizing system new design friction roller, New Design “Eco-Coupling” energy saving maintenance free, New Design “Eco-Blower” by intelligent suction control system, Overhead Travelling Cleaner.

AB45/180525/BY/

Savio Orion Automatic Winder

Quantity: 1, Year: 2001, 52 spindles, Model E, Double loader , Uster Quantum O30 F23 foreing fibers, Exit cone 6″ 4°20, Splicer mesdan 690 1 R replaced new on the year 2022), 2 robots, Waxer, Magitex Blower, 380 V 50 hz, Condition: Running.

AE30/180525/

Saurer Open End BD7

Quantity: 3, Year: 2020, Model: BD7, 480 ROTORS, 34/54mm rotors, Corolab yarn clearer, Running on mill floor.

AE30/180525/

Trutzschler Blowroom Line with TC10-3 Cards

Trutzschler Blowroom Line

Year: 2020

1X Bale Opener BOA-2300

1X Truzschler Multimixer MX-I with CL-C3

1X Truzschler SP-DX

1X Truzschler CL-P

1X Truzschler BR-CO

with:

9X Trutzschler Cards

Model: TC10-3, Year: 2020, Can Changer: automatic, Can Diam.: 40, Flat Type: Aluminium, Three lickerin.

AA94/160525E/TT-T/F/

HOUGET DUESBERG BOSSON RING SPINNING FRAME

Quantity: 1, Year: 1983, Type CBY².116

single side, 110 spindles, ring Ø 160 x 25,4 mm, pitch 200 mm, tubes 600 mm, cop lifter, motor 380 V, 56,5 Kw.

AA05/170525D/TP.L-AY/F/DI/

Seydel 871 & 850 Breakers

AA05/170525D/LO.L-AI/F/DI/

Seydel 871 Breaker

Quantity: 1, Year: 2000

AA05/170525D/AP.L-AI/F/DI/

Seydel 850 Breaker

Quantity: 1, Year: 1994

Loaded in 2 x 40" containers.

Machines stopped on Mill Floor.

AF36/170525/BX/

Complete Open End Spinning & Weaving Plant

Open End Spinning:

Department 1:

1x L.T.G Air conditioner, Year: 2000

1x Trutzschler BDT 019/1720 Blendomat, Year: 1994

1x Trutzschler BOA 1200 Bale Opener, Year: 1995

1x Trutzschler CVT 4 1200, Year: 1995

1x Rieter B5/5, Year: 1988

2x Trutzschler RSK 1200, Year: 1994

1x Trutzschler Card D740 , Year: 1990

6x Trutzschler Card D760 , Year: 1994-1995

5x Vouk Draw Frame SH2/2 & SH2/D2, Year: 1989-1991-1994-1995

1x Schlafhorst SRK Autocoro

3x Schlafhorst 33283-33284-33285 Autocoro, Year: 1996

2x Schlafhorst 36776 Autocoro, Year: 1998

1x VTS07 Twisting

1x ROF Tanners ASSEMBLER, Year: 1981

1x Murata 92 Bobin, Year: 1992

1x Zetascan SERIPlANE, Year: 1992

1x James Heal DYNAMOMETER

1x Mecdan Nap pressure monitor, Year: 2007

1x James Co Reel

1x Nesdan Lab, Year: 2002

1x Uster Tester 3, Year: 1995

Department 2:

1x L.T.G Air conditioner, Year: 1990

1x Trutzschler BDT 019/1720 Blendomat, Year: 1990

1x Trutzschler SRS6, Year: 1990

1x Trutzschler LVSA, Year: 1990

7x Trutzschler Card DK740 , Year: 1990-1991-1992

1x Rieter E5/3 Unilap, Year: 1995

4x Rieter E7/3 Unilap, Year: 1995

6x Vouk Draw Frame SH2/D,E & SH2/D & 125003M0620 & 125003M0619, Year: 1990-1991-1992-2003

3x Marzoli BC165 Roving Frame, Year: 1990-1992

14x Zinser 321E Ring, Year: 1990-1991-1992

2x Schlafhorst X5 Autoconer, Year: 2011-2013

Weaving:

16x Picanol Gamma R6 Looms, 220 cm, Year: 1999

Note: LANCES GUIDEES, POULIE REDUCTRICE, VERSION LDEC, TYPE DE RATIERE 2600, ELSY, 20,, LAMES, 20 TIRANTS, PREDELIVREUR (6), NOMBRE D’ENSOUPLE :(32), NOMBRE DE TOILIERS (29), DIAMETRE De FLASQUES : 800mm

20x Picanol Optimax-i-4-R-Looms, 190 cm, Year: 2016

Note: LANCES VOL LIBRE, OPTIMAX -1, VERSION LDEC, NOMBRE DE COULEUR (4), TYPE RATIERE STAUBLI $3000: 20 LAMES, ELSY, 12 LAMES, 12 TIRANTS, PREDELIVREUR (2), NOMBRE D’ENSOUPLE: 1,5/MACHINE, NOMBRE DE TOILIERS: 1,5/MACHINE, DIAMETRE D’ENSOUPLE : 800mm, NOMBRE DES MACHINES AVEC JACQUARETTE (05) , NOMBRE DES MACHINES sans JACQUARETTE (15)

21x Huayi Waterjet Looms HY708, 190 cm, Year: 2013

20x Nissan Waterjet Looms LW 551, 190 cm, Year: 1999

10x Nissan Waterjet Looms GD767, 190 cm, Year: 2002

21x YIIN CHEAN (DOBBY) Waterjet Looms G71 G, 190 cm, Year: 2016

20x YIIN CHEAN Waterjet Looms JW 861, 190 cm, Year: 2001

1x Benninger Warper 640 bobines, Year: 2008

1x Sucker Muller Warper, Year: 1991

1x Oshima OST-150, Year: 2008

1x MB-551F , Year: 2003

2x Knotex noueur Knotting PSE & PS, Year: 1990-1998

2x Pallet truck

1x Carte

AA10/250225E/PL-L/M/

HDB Woollen Ring Spinning Frames

Quantity: 4 , Year: 2×1995-2×1996,Type CBY,each machine with 240 spindles, rings diameter 75 mm, Tubes 360 mm

AA10/200225/

HDB Woollen Card

Quantity: 1, Year: 1997, width 2,50 m, 4 passages + breast roller, double drafting, belt 12 mm, 192 yarn, Servolap type DC

AA10/050325/

Oerlikon Volkmann 2×1 Twisters VTS07-CT

Quantity: 2, Year: 2012, Type VTS07-CT, 192 spindles, Feeding 2 x 6″, can height 350 mm, diameter 180 mm, output 6”.