AC93/061025E/OI-L/F/BG/

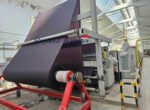

Ramisch Calender

QUANTITY: 1, YEAR: 1987, MODEL RKK 260 NIPCO “I” ESKHER WISS, WORKING WIDTH 2.100 MM, ROLLER WIDTH 2.200 MM

TWO BOWLS CONFIGURATION:

– TOP BOWL CHROMED STEEL ELECTRIC HEATED (DIAM. 340 MM)

– BOTTOM BOWL NIPCO WITH RECOLAN SLEEVE (DIAM. 496 MM)

SEAM AND METAL DETECTOR, METER COUNTER, PRESSURE 60 TN, TWO WATER REFRIGERATED CYLINDERS TO COOL DOWN THE FABRIC BEFORE ROLLING, EXIT BY A-FRAME BATCHER, ONE SPARE RACOLAN SLEEVE IN A BOX (DIAM. 505 MM)

Good condition in warehouse and ready for inspection.

AB60/061025/

Lemaire Thermo-Fixation Finishing Line

Quantity: 1, Year: 2008, Details : frame to unroll the fabric / ERHARDT&LEIMER ET unit with motorized cylinder and pressure roll / J-box with optical detection / LEMAIRE unit with system to brush the fabric at both sides with aspiration system / MAHLO fabric rectifier with 4 correction rolls with total 4 camera’s / LEMAIRE thermo-fixation calander type SMZ year of construction 2008, fabric width up to 3400mm, CAL08*400V, air pressure 6 bar, with aspiration system / motorized exit unit.

AC93/041025/

BIANCALANI SOFT SETTING

QUANTITY: 1, YEAR: 2003, MODEL QUATTRO, STEAM HEATED, FOR WASHING AND SOFT SETTING

AD81/021025E/ATO-AC/C/

Benninger BEN-SIZETEC Sizing

Quantity: 1, Year: 2001, Sizebox TKV, Working width 2000 m, Beaming machine Modell BB, max. nom. working width 2800 mm, max. beam flange Ø 1100 mm, Speed up to 140 m/min.

Dryer: 10 drying cylinder Ø 800 mm, length dry dviding zone 4500 mm.

Warp beam creel Modell ZA: , for max. 16 warp beams, Working width 2000 mm, max. beam flange Ø 1016 mm.

Without warpbeams, without size kitchen, Sizebox: cylinders renewed End of 2023, incl. Spare Parts (reserve cylinders etc.)

AB72/021025/

Osthoff Singeing Range

QUANTITY: 1

YEAR: 2001

WW 1850 MM

ROLLER WIDTH MM.2000 (WORKING WIDTHMM.1850 )

MACHINE HAS HAD THE BURNERS OVERHAULED WITH BRAND NEW FIRE BRICS 2 YEARS AGO SO THE HEART OF THEMACHINE IS LIKE 2 YEARS OLD.

CONSISTING OF:

ENTRY FRAME WITH GUIDING BRUSHING-BEATING UNIT MADE IN STAINLESS STEEL

OSTHOFF SINGEING – MODEL U 97 BURNERS TYPE DOUBLE-JET

4 WATER COOLED ROLLERS WITH AUTOMATIC SELF-BURNER TURNING DEVICE ON E STOP OF MACHINE. THE BURNERS HAVE THREE WORKING POSITIONS:

WITH FOLLOWING ADJUSTABLE PARAMETERS:- FLAME HIGHT – FLAME WIDTH – FLAME INTENSITY.

N.1 OSTHOFF BRUSHING / BEATING UNIT –MODEL VP 97 – WITH

N. 02 BRUSHES CYLINDERS AND

N. 02 OSTHOFF SINGE UNIT WITH 2BURNERS TYPE U 97 WITH FLAME QUENCH SYSTEM

N. 02 BEATERS CYLINDER- WITH SUCTION DEVICE

N.1 OSTHOFF EXIT WITH PLAITER UNIT DRIVEN BY A/C MOTOR

N.1 MAIN CONTROL PANEL WITH AC FREQUENCY INVERTERS

N.1 OPERATORS REMOTE STATION WITH ALL CONTROL PARAMETERS.

IN PERFECT WORKING CONDITION.

AB31/011025/BG/

Kusters Calender

Quantity: 1, Year: 1986 Renewed, Type 212.50-1800. Roller Width 2.000 mm. Working Width 1.800 mm. Pressure 50 TN. 2 cylinders Upper roll Steel Heated by Gas. Lower roll Flexroll NIP/ Manchon. Unit Pneumatic for cooling cylinders. E+L Metal Detector and Seam Detector. High entry with worker platform. Exit by Big Batcher for A-Frame.

AA10/290924E/CRL-AL/M/

Arioli Washing

Quantity: 1, Year: 2015, Type Uniwash, w.w. 2.20 m, 5 washing boxes.

AC44/250925/

Kusters Bleaching Line

Quantity: 1, Year: 1991, Max. Fabric width 3600 mm, Roller surface width: 3.800 mm

Drive side: left, Service side: right, Mechanical speed: 150 m/min, Production speed: 120 m/ min

Electrical tension: 3 x 380 V 50 Hz with MP, Control tension: 220 Volt, Compressed air pressure: 7 Bar , Steam: 2,5 – 3,0 Bar Saturated Steam , Please contact us for a detailed description

AC44/250925/

TVE ESCALE Discontinuous Washing line

Quantity: 1, Year: 2022, Model/Type: HYDRA L 160

Working Width: 3400 mm

Configuration:3 Washing Boxes, 2 with rollers, 1 with central drum

Dosing System:Equipped with 6 dosing pumps

Electrical:

Voltage: 400 V (3AC), Power: 62 kW, Frequency: 50 Hz, Speed: Maximum: 200 meters/minute, Bidirectional operation (both directions)

Processes Capable Of:

Desizing, Scouring, Bleaching All types of washing Exit Configuration:, With Big Batcher,

Condition:, As new – Recently manufactured in 2022, Ideal for high-performance wet processing applications

AE02/230925E/OS-O/M/

Klieverik Calander

Quantity: 1, Year: 2016, Type: TC 131-2000, ww. 2000 mm.

The max. weft width is 1800 mm, The width of the felt is 2000 mm (replaced in 2021)

Dia. heating roller is 760 mm, Heating is thermo oil HTT (gas fired), max temp is 240°C

Some spare parts, In 2021 the system of the machine was modified to be able to use also smaller rolls and to use wefts from A-frame. Additionally a J-box for storage was added.The price for the heating system is extra and is 12.500 Eur.

AA02/230925/

STORMAC Rotary Screen Printer / DONG WON ROLL Embossing Calender / XETMA VOLLENWEIDER NAPPER (LIKE NEW)

1x (LIKE NEW) STORMAC Rotary Screen Printer

Year: 2016 (used very few hours)

By Storvec Industries (A Division of SPG Prints, Netherlands)

Model RD8 Serial number S-113

8 Colors

188 cm Belt width

177 cm Roller Width

165 cm Fabric Printing Width

64/105 AL Stork Screens ( 640mm Circumference )

Screens are Magnetic and Manually Adjustable

4-80 Meter/Min Fabric Speed

169 kW Mechanical Power

With Apollo Drier, 4 chamber, Natural Gas, Single Pass

With Weft Straightener

With Control Panel and inverter controls

3-Phase, 480 VAC, 50/60 Hz

1x (LIKE NEW) DONG WON ROLL Embossing Calender

Year: 2013 ( with very few running hours )

Model DWEBC-1800 – serial number 13013

Made in South Korea

1800 mm Max Width

2 Roll

(1) Chrome Steel Heating Roller 10 inch diameter

80 inches face width

(1) Ceramic Roller 16 inch diameter

71.3/8 inches face width

Max pressure 80 kg /cm2

Running 60 kg/cm2

Fabric plating frame

A Frame Exit

480-220 V, 60 Hz

1x (LIKE NEW) XETMA VOLLENWEIDER NAPPER

Year: 2208

Model Multi System XREB

Made in Germany

Working width 220cm

86 Inches face width on the wire rollers

12 sets of 3 interacting wire roller sets

Single Action wire

Multi Function Raising and Emerizing capabilities

Flock suction unit with 4 Vertical dust bags

Entry and exit at same side

Exit with folding plaiter

84 KW connected Power

AB46/230925/AR/

Menzel Coating Range

General description:

Different methods of production can be realized, machine is designed for coating on a precisely high coating roller or as an air doctor blade.

Equipped with a collision control system.

Machine consists of:

1. Lower frame and coating head with length, beam and knife adjustment,

2. Coating roller with stripping doctor device (which helps to remove residues from the rear roller)

3. Brake, paste limitation, paste supply, control panel

4. Lacquering device – serves for lacquering the before coated material.

5. Consists of a frame, engraved roller, pressure roller, medium basin and medium limitation.

6. Coating beams adjusted with servo drive controlled via the control panel from which all functions of the machine a centrally controlled.

7. Coating knives: adjustable

8. Mahlo coating thickness verifier system, entry and exit

9. 1 Preheating unit for fabric, run with hot water

10. Heat exchanger & transfer by H.E.A.T. Inc

11. Model KM550-80-483 , 80 Kw, max. temp. 550 F, max. press. 75 psig,

12. Voltage: 480V 60 Hz

Specifications:

Year: 2005

Roller width: 2800 mm.

Coating roller with doctor stripping device

Coating beam equipped with 2 coating knives

Material width: 2600 mm.

Speed: 3-35 m/min.

Burner Capacity: Zone 1 (inlet) 150 Kw, Zones 2-5 100 Kw

Voltage: 3x 480 V AC, +/- 10%

Frequency: 60 Hz

Control Voltage: 24 V DC

Compressed air: 6 bar

AD63/230925/

KMT (now SALVADE) Calender For Transfer Printing on Fabrics

Quantity: 1, Year: 2002, Manufacturer: KMT (now SALVADÉ), Model: COMBI 620 SSA

Cylinder Diameter: 600 mm.Useful Working width: 1.650 mm.Transfer Paper width: 1.650 mm.Transfer Paper Diameter: Up to 280 mm.

Protective Paper width: 1.800 mm.Protective Paper Diameter: 300 mm.Max. Speed: Up to 15 m/min.

Cylinder heating: electric, bilateral dogal centering device

NEW felt conveyor belt installed a few months ago

Max. Installed Power: 45 Kw.Delivery in roll

Suitable for woven and knitting fabrics and for VERY LIGHT KNITTING fabrics.

AC93/230925/

Comes Wash Range with Corino Entrance

QUANTITY: 1, YEAR 1999, ROLLER WIDTH 2.300 MM, TO BE INSTALLED BEFORE THE STENTER, TO WASH ENZIMES FROM THE SPINNING PROCESS IN ACRILIC FABRICS.

ENTRANCE WITH J-SCRAY AND CORINO GUIDER, DOUBLE WASH TANK WITH INTERMEDIATE PADDER

DRIVEN CYLINDER FOR TENSION CONTROL, SUITABLE FOR ELASTIC AND KNITTED FABRIC, TO BE INSTALLED BEFORE THE STENTER

SPECIALLY DESIGNED TO WASH ENZIMES FROM THE SPINNING PROCESS IN ACRILIC FABRICS, BETA PADDER, 3 CYLINDERS, ROLLER WIDTH 2.400 MM AND DOUBLE IMPREGNATION TROUGH

EVAC VACUUM SLOT

AB46/220925/AR/

Benninger Synthetic Zell Sizing

Quantity: 1, Year: 2001, Model: BEN FULLSIZE, Consisting of: ZMF-WKD-KSA-TF-MLT-TF-TW-BBA, Set up as a 1 beam to 1 beam sizing ( no sectional creel), Working width: 2800 mm. Max production speed 0,14-125 m/min, Draw tension : 15daN- 30 daN, 30 daN-300daN, Chain system, Protection device, With catwalk, 200 mm. Diam. feed roller, motorized unwinder, humid device, Finishing device, subfield, dance roller, Winding train, Voltage Transformer in 3x 480 V / 60 Hz – out 440V /60Hz

Control voltage 230V / 60 Hz, Main Fuse 20 A, Main control cabinet climatized, Updated touch screen by Simatic, Panel PC, With handheld run controls entry and exit, Anti static system, Protechna Laserstop 4080, 1 size tank with 3m width rolls inside, one red rubber coated roller and 1 black rubber coated roller

2 Double squeeze roller sets each set, with one vulcanized rubber and one chromed cylinder , 2to & 5to.

AD63/210925/

Mezzera after Printing Washing

Quantity: 1, Year: 2014, Model: CONCORD, After-print washing for fabrics in rope form for knitting fabrics and woven fabrics. 12 fabric rope washing channels, Automatic chemical dosing system, Electrical cabinet, Rope-opener and squeezer mangle.

AD63/210925/

Salvade Calender

Quantity: 1, Year: 2013, Calender for transfer printing on fabrics, Model: COMBI 620, Cylinder diameter: 600 mm, Working width: 1.800 mm, Transfer Paper width: 1.800 mm, Protective Paper Diameter: 300 mm, Max. Speed: Up to 18 m/min, Cylinder heating: electric, Delivery in roll, Felt conveyor belt installed new a few months ago, Max. Installed Power: 37 Kw, Suitable for woven and knitting fabrics.

AD76/160925/AS/

Pluvia Rope Washing Machine

Quantity: 2, Year: 2018, 2 pcs open width washing tank (200 cm width), 10 rope washing chambers, Beneks brand rope opener (2019 model, 200 cm width)

CONDITION : Installed and running rituation

AC93/180925/

Benninger Wash Range for Woven Fabric

Quantity: 1, Year: 2003, ROLLER WIDTH 2.200 MM, 7 TANKS: 5 DRUM TYPE TANKS AND 2 TIGHT STRANDS TYPE, Material: linen, PE/CV, %100 Cotton, Lycra blends, Weight: 100-400 g/m2, Working width: 2.000 mm, Total roller width: 2.200 mm, Min. working width: 950 mm, Speed range of the multi-motor drive: 6-60 m/min, Average production speed: 45-60 m/min, Voltage (phase-phase): 3 x 400 V +/-10%, Frequency: 50 Hz +/- 2%, Water pressure required (overpressure): min. 2 bar/max. 4 bar, Saturated steam required (overpressure): min. 4 bar/max. 6 bar, Compressed air pressure required: min. 7 bar /max. 12 bar , Water per 1 kg of cloth, Total: 6-18 lt, Steam per 1 kg cloth, Total: 0.6-2.0 kg, Total with heat exchanger: 0.4 – 1.2 kg.

AC93/180925/

Benninger Bleaching

QUANTITY: 1, YEAR 2003, ROLLER WIDTH 2.000 MM, ENTRANCE WITH J-SCRAY ACCUMULATOR, 2 IMPREGNATION TANKS, BENNINGER IMPACTA CHEMICAL DOSING UNIT, STEAMER, TIGHT STRAND, AND ROLLER BED PASSAGE, 3 TANKS BENNINGER EXTRACTA WASH RANGE, J-SCRAY ACCUMULATOR, EXIT BY FOLDER AND A-FRAME BATCHER.

AD63/190925/

Salvade Continuous Steam Flash Ager Steamer after Printing

Quantity: 1, Year: 2018, Model: VPM, Roller width: 2.300 mm, Working width: 2.000 mm, Fabric content inside machine: 180 mt, Fans for steam recycling, Rotating inlet spreader with bypass system and Teflon-coated cylinders, Conveyor belt for introducing elastic fabrics (Mesh and Shuttle) with end-of-fabric photocell, Protection paper winding unit with constant pull control, Predisposition for high temperature operation, Adjustment of rotation speed of fabric holder rods, Automatic chain lubrication, Teleservice, Fan adjustment by inverter, SuperWet Temperature control and steam saturation system, Walkable grille 180 m, End-of-fabric photocell, One hot Teflon-coated and controlled cylinder diam. 220 mm w.w. 2000 mm, Controlled roller entry for elastic and delicate fabrics, Automatic humidification system, Steam consumption control, Automatic steam regulation valves, Entrance and exit same side with conveyor belt, Steam distributor in iron DN65 (Clarino), Machine suitable for woven and knitting fabrics.

AB55/170925/

Kuster Bleaching

Quantity: 1, Year: 1991, Suitable for: Cotton Blends and Terry Towel, Working Width: 3600 mm, Electronics: Fully updated with modern PLC system, High-Capacity Steamer, Ideal for continuous bleaching operations, Robust German engineering and performance, Condition: Excellent working order with upgraded automation for enhanced efficiency.

AA07/170925/

Zimmer Chromojet Printing Plant

420 cm

ENTRY UNIT

ZIMMER PRINTING MACHINE 8 COLORS POSSIBLE UPGRADE TO 12 WITH 1024 JETS

MllTER STEAMER

WASHING AND VACCUM UNIT

COBBLE STENTER DRYER

EXIT UNIT

ZIMMER COLOR KITCHEN

SUPRAMIX

ZIMMER SAMPLE PRINTER

STEAM GENERATOR WITH THERMAL OIL CIRCULATION

WASTE WATER TREATMENT AND RECYCLING UNIT ENVIROCHEMIE (COMPACT)

AB55/170925/

TVE ESCALE Semi-Continuous Washing Line

Year: 2022, Model HYDRA, Working width 3400 mm.

Fabric entry from big roll with double motorized spreader and BIANCO dogal centering device

No. 3 tanks of which: the two lateral ones with rollers and the central drum tank

No. two suction pumps complete with suction bars to create the “vacuum” washing

Fabric exit in big roll with tangential winding

Dosing system for no. 6 products complete with no. 6 dosing pumps

Electrical panel

Suitable for: desizing, scouring and bleaching

AB55/170925/AR/

Small Printing Plant

AB55/140825D/ATI-AI/F/AR/

SPG Prints STORK ROTARY PRINTING MACHINE

Year: 2019

Model RD8 ID

Working Width 2000mm

16-color Rotary Screen Fabric Printer

2000mm Roller Width consisting of the following:

J-Scray with Pull Roll Infeed System

Stovec Web Guidance System added in 2021

16 Color SPG RD8 ID Rotary Screen Print Block

Stovec 3 Zone, Gas Fired Dryer 180 degrees C

Exit Plaiter

All Pumps, Motors, Siemens Simatic Controls, Gas Train Assembly, Drive Cabinets and Electrical Cabling

Fimat Color Straining Machine, Year 2019

Fimat Rotary Screen Washer, Year 2019

Fimat Drum Washer, Year 2019

Machines are on Mill Floor.

AB55/140825D/RRP-CR/M/AR/

SPG Prints Digital Printer with Dryer

Year: 2019

Working Width 2200mm

36 Heads Year 2019 Consisting of the following:

AC. Corino In-feed, Type Big Roll

2200mm Roller Width, 10m/min

AD. SPGPrints Austria GmbH Model Javelin 1850 Mk 1.2 Digital Textile Printer

1200 DPI 1850mm working width

Wide-format printing

Short and long run capability

AVACAD and ARCHER digital software

A-Frame Indeed with Compensator

Spectrometer

AE. SPGPrints Austria Gas Fired Dryer

Machines are on Mill Floor.

AB55/170925/

SPG Prints Digital Printer

Year: 2019, With Dryer, 36 Heads.

Consisting of the following:

AC. Corino In-feed, Type Big Roll, 2200mm Roller Width, 10m/min, Year 2019

AD. SPGPrints Austria GmbH Model Javelin 1850 Mk 1.2 Digital Textile Printer, 1200 DPI, 1850mm working width, wide-format printing, short and long run capability, AVACAD and ARCHER digital software, A-Frame Indeed with Compensator, Spectrometer

AE. SPGPrints Austria Gas Fired Dryer

Machine Ran 50 hrs only, Brand New.

AB55/170925/AR/

Stork SPG Rotary Printing

Quantity: 1, Year: 2019-2020, Roller Width 2000 mm, 4 Chamber Dryer, Machine only ran few hundred hours Brand New Condition. With Spares and Acessories. Status : Installed.

AA10/160925/

Babcock Open Width Bleaching Range

Quantity: 1, Year: 1996, Width 240 cm, w.width 220 cm, for knitted & woven fabrics, tensionless, with 2 vats, 1 steamer and 4 washing vats.

AA10/160925/

Osthoff Singeing

Quantity: 1, Year: 1998, suitable for wool fabric

width 2000 mm, composed of: CORINO Centering device, Brushing and beating group right and reverse

1 Singeing machine right and reverse, 1 Right Brushing and beating group, 1 Reverse Brushing and beating group, Exit folding system

AA10/160925/

MONFORTS Sanforizing Machine TOPTEX

Quantity: 1, Year: 2003, working width 2200 mm, for knitting fabric

AE02/150925/

Fabric Finishing Plant

1x Bruckner stenter frame HN, year 1991, ww. 600 – 3600 mm, 7 chambers, steam heated

2x LAP-PRO Benninger jigger, ww. 3200 mm, year 2017

1x LAP-PRO Benninger jigger, ww. 2200 mm, year 2017

1x LAP-PRO Benninger jet dyeing machine, capacity 200 kg, year 2017

1x LAP-PRO Benninger jet dyeing machine, capacity 400 kg, year 2017

2x LAP-PRO dosing stations, year 2012 / 2017

2x Maag fabric inspection machines, ww. 2000 mm, year 2018

1x Alex inspection machine, ww. 3400 mm, year 2018

1x Maag selvedge printing machine, ww. 3200 mm, year 2018

AI55/150925E/LP-AI/M/

Ramisch Calender RKK 530

Quantity: 1, 5 cylinders of which 2 cotton 2 teflon and 1 steel, 50 Ton .- power supply, 2200 mm face roller width, 2000 mm working width.

AD63/110925/

Lafer Carbon Brushing Machine For Peach Hand

Quantity: 1, Year: 2003, Model: Ultrasoft, Rollers width: 2000 mm, Useful working width: 1800 mm, Fabric entry from a plate, Centering device, 6 rotating carbon brushes, Fabric exit from plate

AA10/090925/

Cibitex Sanforizing

Quantity: 1, Year: 2007, Table width 2000 mm, Working width 1800 mm, Steaming cylinder 678 mm, Shrinking group dia.610 mm, with rubber belt 1960 mm, thickness 67 mm, Drying Felt Calender main cylinder dia.800 mm.

AE56/080925D/SL-AI/F/BA/

KD Decatizing Machine

Quantity: 1, Year: 2020, Italy brand, Maximum dia 180cm, Steam heated.