AJ01/200126/CJ

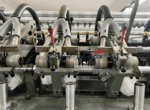

Lezzeni Assembly Twisters

Quantity: 3, Year: 2009, Type BR/H 300, 2 machines with 72 spindles and 1 machine with 36 spindles, Gauge:300, Ring diameter 229, ring height: 400.

AB45/200126/BY/

Giesse AC97/EM Chenille Machine

Quantity: 1, Year: 1997, nos. 80 spindles, Rotating blade system, ring size diameter 120mm, Standard creel, Tubes 450 mm, Gauge 180 mm, 380v/50hz, ondition: Used in excellent condition.

AJ01/200126/CJ

LEZZENI TBR DELTA Twister

1 LEZZENI Twister double twisters mod.TBR/DL

Machine will be working till April 2026

100% working

AH27/140425D/CS-C/F/

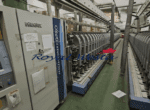

Saurer Volkmann TFO VTS-10-0

Quantity: 25

Year: 2023, new one, never fitted, 200 positions each, pot dia. 137×170 mm.

German machine, original with guarantee.

Machine Origin : Made in Saurer

Main drive KW usage: 30 KW

Main Drive with frequency converter exist or not: WITH FREQUENCY

Twisting Drive with frequency converter exist or not: WITH SERVO

What Voltage and Hertz are used: 380 V 50 Hz

Computer display exist or not Parameters: WITH TOUCH SCREEN

Spindles gauge: 207

No. of sections: 10

No. of spindles per sections: 20

Total No. of spindles: 200

Feed package type: 126 mm

Feeding empty tube dimensions: 38/44/170

Take up package type: taper type

Take up empty tube dimensions length, diameter, (4’20/5’57): Can be configured according to the situation.

Baloon limiter exist or not: NOT

Usable yarn count range: 20-200

Spindle speed range: 1000-12000

Twist range: 80-2600

Paraffin waxes exist or not? NOT

Machine length: 24100 mm

Machine Width: 600 mm

Machine Weight: 4800 Kg / 5800 Kg

AA08/200126E/RR-A.L/F/BO/

Schlafhorst 338 Autoconers

3 Automatic cone winder SCHLAFHORST 338 RM

– n.60 heads each

– manual feeding by spools

– 9-position revolver

– grooved drum 2,5-turn

– pitch 6″ (152 mm)

– conicity 4°20’

– splicer G22

– electronic clearers Loepfe TK 940F

– waxing device

– cone magazine with single basket each head

– conveyor belt for unloading bobbins

– lighting

– blower Sohler

– year of construction 2006

AB15/200126/AX/

GAUDINO Ring Spinning Machines

Quantity: 3

Gaudino FPB 99 / 260 / La, 1999 Ring spinning, 704 Spindles – Auto doffing – SKF PK 1601 draft – 82.5mm Pitch – 55mm ring diameter – 260mm tube length -SKF silent spindle – spinning finger – Magitex blower – double drive

Gaudino FPB 99 / 260 / La, 1999 Ring spinning, 640 Spindles – Auto doffing – SKF PK 1601 draft – 90mm Pitch – 60mm ring diameter – 260mm tube length – spinning finger – Magitex blower – double drive

Gaudino FPT 260, 1998 Ring spinning 640 Spindles – Auto doffing – SKF PK 1601 draft – 90mm Pitch – 60mm ring diameter – 260mm tube length – spinning finger – Magitex blower – single drive

AA10/190126E/OS-Y/F/AQ/

Volkmann VTS 05-C Double Twisting (2×1) /Cabling

Quantity: 1, Year: 2012, mod. 05-0 type 8.02, 40 heads (20×2), feeding 10″, free ballon, can dia.350 mm., delivery 10″, pneumatic doffing and air threading device. Machine running.

AC32/160126D/TP.L-R.L/F/BC/

Schlafhorst X5 Winder

Quantity: 1, Year: 2009, for wool spinning. 40 spindle, CBF, FD Chanel, Yarn clearer : Zenit+, With Waxing, Cone angle : 3 deg 30′, With Theromo Splicer, OHTC, Condition : Stop on mill floor Jan 2026.

AC32/160126/BC/

Zinser 421 E Ring Spinning

Quantity: 3, Year: 1991, Ring Frame for wool spinning, Type : 421E, 3 set x 472 spindle, Ring Guage: 75mm

Ring Dia : 50mm x 2 set With attached Lycra device : 2 set / 45mm x 1 set Without Lycra device ( Normal )

Condition : Stop on mill floor Jan 2026

AC86/160126/AQ/

Savio 2×1 Twisters GEMINIS

Quantity: 2, Year: 1996, mod.GEMINIS 204B, 216 spindles, Duopot feeding 6″ 4°20 x2, gauge 200 mm., delivery 6″, 4°20, air threading device, blower.

Machines sold without splicer.

AE30/150126D/ARP-AC/F/

Saurer BD480 Open End

Quantity: 1, Year: 2019, 512 Rotors, Rotor size: 34mm, With yarn lifting, Running on mill floor.

AA08/150126E/AYI-O/F/AQ/

Sant’Andrea RF4/A Finishers

Quantity: 2, Year: 2002, 16 heads, Rack for 32 cans 800 x 1200.

The machines worked until December 22, 2025.

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/RL-C/F/AQ/

Zinser 421E Ring Spinning with Pinter System for Lycra

Quantity: 1, Year: 1992, 580 spindles, With Magitex blower and Pinter system MA1 from 2023, gauge 82.5, ring 51, tube 260.

The machines worked until December 22, 2025.

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/CY-A/F/AQ/

Zinser 421E Ring Spinning

Quantity: 1, Year: 1992, 580 spindles, with Electro blower, gauge 82.5, ring 51, tube 260.

The machines worked until December 22, 2025.

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/RYI-AO/F/AQ/

Saurer / Zinser 451 IMPACT FX Ring Spinning

Quantity: 4, Year: 2018

Link: Vaporfil VAP L40-Automatic cone winder Saurer Schlafhorst Autoconer X6

576 spindles, with Magitex blower, gauge 75, ring 45, tube 220

The machines worked until December 22, 2025

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/RL-C/F/AQ/

Schlafhorst Autoconer 5

Quantity: 1, Year: 2007, 24 heads with bobbin loader, 6” output.

The machines worked until December 22, 2025.

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/RCI-AT/F/AQ/

Saurer / Zinser 451 IMPACT FX Ring Spinning

Quantity: 2, Year: 2016

Link: Vaporfil VAP L40- Automatic cone winder Saurer Schlafhorst Autoconer 6

576 spindles, with Magitex blower, gauge 75, ring 45, tube 220

The machines worked until December 22, 2025.

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

AA08/150126E/TSI-RLI/F/AQ/

Combing PB33, Sant Andrea Blending, Gill Boxes

1x Blending machine Sant’Andrea 2M, Year: 1997 – Output can 700 x 1000

1x Intersecting Sant’Andrea CSN, Year: 1994 – Output can 700 x 1000

5x Combing machines NSC PB33 LJ, Year: 2003-2006 – Output can 800 x 1200

2x Intersecting NSC GC15

1x Intersecting Sant’Andrea CSN

1x Intersecting Sant’Andrea SHE 24, Year: 2011

The machines worked until December 22 Year: 2025

All the relevant cans, finishing tubes, and all spare parts available at the factory will be delivered with the machines.

All the machines are in perfect condition, fully functional, and have always processed 100% wool for weaving sector.

NOTE: FOR SALE AS ONE LOT

AA02/130126E/LTI-CI/M/BY/

Oerlikon Barmag Draw Texturizing

Quantity: 1, Year: 2016, Model eFK-PES, 288 Positions, Double Heaters, Double Sided with Independent drives, Godet Draw Texturing Units, Double Creels, Lycra Attachments.

AF08/130126/CM/

Ratti Two For One Twisting

Quantity: 2

Year: 2003

Type: R325 N/100/10. NT260

Cheese type, spindles diameter of 260 mm, take up tube of 230 mm, take up package of 5 Kg

Stopped at factory floor, machine was ready for loading.

AB45/110126/BY/

Trutzschler Drawing Frame

Quantity: 2

1x Year: 2014, Model TD7:

No autoleveller, Automatic can changer , Feeding can size 1000 mm diameter / 1100mm length, Exit can size 600 mm diameter / 1150mm length, 380 V 50 Hz.

1x Year: 2014, Model TD8:

Autoleveller , Automatic can changer , Feeding can size 600 mm diameter / 1150mm length, Exit can size 500 mm diameter / 1020mm length, 380 V 50 Hz.

Condition: Running

AA10/120126/

Rite Assembly Winder & Volkmann VTS 06 Twisting

1x RITE Assembly winder mod.ARD-L, Year: 2007, 24 heads, run 10″, autodoffing, creel 3 ends, possible up to 12 ends.

1x VOLKMANN 2×1 Twister mod.VTS.06.S, Year: 1997, 132 spindles (66×2), independent sides, feeding 270×56 mm, delivery 280x67x36 mm, central conveyor belt, air threading device.

AB45/100126/AQ/

Simet Electronic Winders

Quantity: 2, Year: 2001, Model SE3 winder, Heads: 3 & 6 , 6″ 4°20’, waxer , Dismantled.

AB45/080126/AQ/

Corghi Winders

Quantity: 2

1x Corghi model BR12-T2-P36 winder, Year 2003, 12 heads, 6″ 4°20’, waxer, Dismantled.

1x Corghi model BR-A winder, Year 2003, 24 heads, speed/min 750, 6″ 4°20’, waxer, Electrojet blower, Dismantled.

AB88/090126/

HDB (Houget Duesberg) Carding Machine

Quantity: 2

1x 2,200 mm working width, three sections (opener, pre-carding, and can), with Blamir trolley.

1x 2,500 mm working width, with 2 feed cylinders and weighing system.

AC09/090126/

Schlafhorst SE12 Open End ACO480

Quantity: 2

1x SAURER AUTOCORO 9 Open End Spinning Machine, Year: 2016

No. of Rotos : 360, Yarn Clearer: Corolab XQ, Measuring Head: XQ, No. of Piecer Carriages: 4, Opening Roller: B174DN, Rotor Diameter: 48 mm, Length Measuring: Available, Delivery Package: Cone, Conicity: 1’50’, Waxing: Available, Inverter Suction Motor: Available, Flexpack FX: Available.

1x SAURER AUTOCORO 10 Open End Spinning Machine, Year: 2023

No. of Rotors: 768, Yarn Clearer: Corolab, Measuring Head: XQ, Opening Roller: B20 DN, Rotor Diameter: 30 mm, Rotor Type: G630 BD, Length Measuring: Available, Spinbox: SE 20, Conicity: Cylindrical, Waxing: Available, Multilot: 3, DCU (Doffer): 6, Synchro Piecing: 36, EVA: Available, SDSI: Available, Upper Thread Sensor Monitoring: Available, Tube Selection (Colour Sensor): Available, E-Drive: Available, Pilot Spinning: Available.

AI08/080126/BA/

Line Tow to Tops Breaker for Polyester, Schlumberger NSC

Composed of:

1x TT11 Breaker/Cutter, Year: 1991.

1x GC13 Gill, Year: 1988.

1x GC12 Gill, Year: 1986.

1x GC14 Linked Bump Press, Year: 1992.

Machines are high quality and have not worked full shifts and had less orders during production.

It is very good condition, the machines worked just few days a week.

AC86/160126E/AC-R/F/AQ/

SAVIO ESPERO

32 threads from cone to cone

I used it to make dyeing cones and wax the dyed yarn.

I am a knotter and weaver.

AB46/080126D/AA.L-C/F/

Gilbos Cone Bitwinders

Quantity: 8, Year: 2007/2008/2009, Type BITWINDER, Single Head, Technical details : 15 position carousel, splicer, to rewind rest yarn from cylindrical cones to a bigger cylindrical bobbin course.

4 machines complete 4 machines for spare parts

7 machines can fit in 1 x40′ Ctr

AI08/070126/BA/

Acrylic Fiber Line: TB20 Breaker & GC30-D5 Rebreaker

Quantity: 2 Lines

Include: TB20 and D5GC30

1 x NSC Schlumberger TB20 Breaker, Year: 2012, with chiller, exit can dia 1000×1200 mm.

Machine is in production (Nov 2025)machine can be tested running before shipment.

1 x NSC Schlumberger GC30-D5 Rebreaker, Year: 2012, 5 rollers, autoleveller, bobbin exit.

Shipping Requirement are: 2×40′ HC.

From tow to top for acrylic fiber.

AH25/070126E/RRL-RL/F/AQ/

Production Line Includes: Texturing, Twisting, Dyeing, and Packing

1x GIUDICI Texturizing:

Year: 2002, mod .TG30 FA , 84 position, Designed for polyester yarns ranging from 10 to 300 denier.

Work from 40 dtex to 600 dtex polyestere nylon and polipropilene, full automatics.

1x IMPIANTI NOVOPAC Packaging Machine

Year: 1997, Model: ARF500 + 1406B.

2x MENEGATTO Texturizing:

Year: 1999, Model: TMA 43, Total Spindles: 168 (84 per side), Sections: 7 per side.

Texturizing Ovens: 84 high-temperature electric ovens (1000 mm length, 100–650°C range)

Fixing Ovens: 84 high-temperature electric ovens (700 mm length)

Feeding Shafts: 4

Rotary Creels: 14, each with 24 bobbins arranged over 3 floors

Drive System: 168 TEMCO drive belt spindles

Cooling System: Forced cooling with refrigeration and fume extraction

Control System: Electronic control with Menegatto software

Doffing: Manual or automatic

Work from 40 dtex to 600 dtex polyestere and nylon and polipropilene, full automatics.

1x OBEM Dyeing and Steaming Machine

Year: 1997, Model: 97003

1x RPR Texturizing:

Year: 1997, Model: 3SDX4

Take-up Positions: 168

Total Power Consumption: 143 kW

Yarn Compatibility: Polyester yarns ranging from 33 to 330 dtex

Production Speed: Up to 1000 meters per minute

3SDX 4 work from 40 dtex to 600 dtex polyestere nylon and polipropilene, Electronics endowed with pc that can change the form of manufacture in automatic; can work both to an oven and to two.n. 4 shaft of workmanship, position of job 84 positions for forehead, total 168, or rather every front can independently work from 84, endowed with plant for punching of the yarn to air; electronic control of the production and the quality.

6x RPR Twisting GC 96:

Year: 1998, Model : GC96D

Number of spindles: 90–96, depending on configuration.

Can/tub diameter: approximately 270 mm; take-up tube length: approximately 230–290 mm

Package capacity: up to approximately 3–5 kg per package.

Motor power: approximately 22 kW; electrical specification 220 V / 60 Hz.

10x VEMATEX Twisting:

Year: 1990, n. 72 spindles melted by cm 250 with centralized taper.

Vematex WB-T — Double Twist TFO Twister.

AA79/070126/

NSC Schlumberger FM8N Roving Frame

Quantity: 1, Year: 1997, Horizontal rubbing frame, 20 spindles, Manual doffing, 355mm pitch, 2 roving’s per bobbin, Input 12 to 15 ktex according to the material, roving weight 0.66 -5.5Nm, draft 9 to 26 by gear box, nsc double apron drafting, draft apron 145 mm wide, rubbing speed 1200 cycles /min maximum, number rubs 5 to 8 per meter, 300mm bobbin, delivery speed up to 220meters/min. Fitted with new drafting aprons, new rubbing aprons, new front air valves, new sliver guides, new barrel holders.

AH25/070126/AQ/

RPR Twisting

Quantity: 6, Year: 1998, mod. GC 96, Number of spindles: 90–96, depending on configuration.

Can/tub diameter: approximately 270 mm; take-up tube length: approximately 230–290 mm.

Package capacity: up to approximately 3–5 kg per package.

Motor power: approximately 22 kW; electrical specification 220 V / 60 Hz.

NOTE: The machine/s in the factory are almost like new (no damage or missing part), because they worked very little. Machines stopped in 2020. Some spare parts are given with the machine/s.

AH25/070126E/YO-O/M/AQ/

Giudici Frictions Texturizing

Quantity: 1, Year: 2002, mod .TG30 FA , 84 position.

Yarn Compatibility: Designed for polyester yarns ranging from 10 to 300 denier.

Double oven and automatic doffing for PES and PAM yarns of whole range of textile titles, yarns ( from 10 to 330 Dtex) full automatics.

Distribuited on 3 floors of collection and 84 TEMCO friction spindles mod. FTS525 ME open/closed, fastly change of torsion, friction and driving disks in ceramic , diam. mm 52 and thickness 9 mm., shaft diam. mm.14,5 , combination disks 1/8/1

Machine equipped with :

Extra roller for the control of tension, quality controller

Air interlacing device (that is regulator of pressure, piping, valves and quick coupling)

GQS System (iudici Quality system) to control the tension of yarn , integrated with the machine.

NOTE: The machine/s in the factory are almost like new (no damage or missing part), because they worked very little. Machines stopped in 2020. Some spare parts are given with the machine/s.

AB74/070126E/AC-C/M/

Gilbos Bitwinder

Quantity: 1, Single Head, Perfect running condition, Machine comes with Splicers.

AB45/070126/

NSC Schlumberger Rebreaker GC30

Quantity: 1, Year: 2005, exit bobbin , Autoleveller,Bobbin dimension widht 335 to 550 (max 600 mm)

Compresser air: min 4 bars, Sliver weight 18 to 32 Ktex, Speed 600 meters per min,Condition: Dismantled

AA05/050126/BC/

Cognetex FTC Ring Spinning

Quantity: 2, Year: 1991, 448 spindles each, Ring día 48 mm., Gauge 75 mm., PK1601 drafting.

AB46/060126/BJ/

Murata Qpro Auto Winder

Quantity: 3

2x Year: 2014, 60 spindles

1x Year: 2015, 50 spindles

Model: Qpro CBF, No of Drums: 60, Yarn clearer: Loepfe Zenit, Measuring Head type: TKYM Zenit FC, FD Chanel, Waxing, Doffer: Available, Suction: Central, ot air discharge: Upwards, OHTC: Murata, GOOD CONDITION.

AA23/050126E/AL.L-R/F/

SAHM Winders

Quantity: 1, Year: 2001, Model: 2002 R, Adaptation: Suitable for double winding with coil size 75 mm × 300 mm

Electrical: 3 × 400 V, 50 Hz, current 5.10 A, calculated power 3.53 kVA

Additional feature: Service/maintenance panel included, Control: 24 V DC width control (so presumably the traverse/width adjustment or winding‐head width control uses 24 V DC)

AA03/050126E/O.L-C/F/

Croon & Lucke/Germany Reeling Machine

Quantity: 1, Year: 1985, Type D800 C, for 2 x 8 = 16 Jumbo-hanks until 3-4 kg, conic and cylindric,circumference 1,60 – 2,30 m, width 200 – 400 mm

380V/3 Ph/ 50 Hz, Machine is in good condition and still in running position.

AA03/050126E/O-C/F/

Croon & Lucke/Germany Reeling Machine

Quantity: 1, Year: 1980, Type Z60C, double sided,

for 5 Jumbo-hanks until 3-4 kg each side conic (copsform) and cylindric , circumference 1300-1900 mm,

pitch 475 mm for hanks until 400 mm width, porcellan traverse rollers,

traverse 220 mm, variable speed, gear motor for opening and closing of reel,

meter counter, 2 carts to pull out the hanks in untied form.

The reel can start again promptly. During the reel is running, the hanks on the cart can be tied up.

AA03/050126E/O-C/F/

Croon & Lucke/Germany Reeling Machine

Quantity: 1, Year: 1980, Type Z60C, double sided,for 5 Jumbo-hanks until 3-4 kg each side conic (copsform) and cylindric

circumference 1500-2337 mm,

pitch 475 mm for hanks until 400 mm width, porcellan traverse rollers,

traverse 220 mm, variable speed, gear motor for opening and closing of reel,

meter counter, 2 carts to pull out the hanks in untied form.

The reel can start again promptly.

AA02/050126/

TRUETZSCHLER CARDING AND RIETER DRAWING

AA02/050126E/CA-A/M/

TRUETZSCHLER Cards

Quantity: 28 , Year of Manufacture 1996 to 1998, Model DK 803, Chute Feed, Can Coiler, 1000 x 1200mm

AA02/050126E/CT-A/M/

TRUETZSCHLER Cards

Quantity: 4, Year: 2002, Model DK 903, Chute Feed, Can Coiler, 1000 x 1200mm

AA02/050126E/CR.L-A/M/

TRUETZSCHLER Cards

Quantity: 6, Year: 1993 & 1995, Model DK 760, Chute Feed, Can Coiler, 1000 x 1200mm

AA02/050126E/RA.L-A.L/M/

RIETER Breaker Draw Frames

Quantity: 4 , Year: 2018, Model SB.D24, Double Headed, Creel for 6 Rovings

, Can Size 600 x 1200mm, Auto doffing, Can Size 600 x 1200mm

AA02/050126E/LI.L-C.L/M/

RIETER Finisher Draw Frames

Quantity: 8, Year: 2018, Model RSB.D-22, Double Headed, Auto Levellers, Creel for 6 Roving, Can size 500 x 1200mm

Auto Doffing, Can Size 500 x 1070mm

AB60/060126/

Corghi Electronic Cone to Cone Winder

Quantity: 1, Year: 1997, model BR12-C2-P24 , (12 working heads with electrical box for 2 units) + BR-A , (12 heads but 10 working heads), year 1997, for winding cylindrical cones 6″ (152mm traverse), max. diameter cone 290mm, 1 coaxial motor per head, optical feeler sensor each head, electronic speed regulation min. 400 – max. 1200 RPM, 380V, 50/60Hz. L x w x h : unit 1 : 220cm x 95cm x 120cm, unit 2 : 200cm x 95cm x 120cm.

AB60/060126E/TY-Y/F/AO/

Rieter Card C70 L

Quantity: 1, Year: 2018, Machine for production up to 120Kg/h, CBA filling machine, Filling for polyester, polyester/Viscose blends and acrylics, Graf filling, Preparation for polyester fibres, Title of carding ribbon 12 Ktex max, Outlet diameter 600mm, Pot height 1200mm, Longitudinal introduction of the can, Separate sliver potting unit for direct floor mounting, Rotating disc for depositing 39 mm channel ribbon.

1x A 21 Series condenser year 2018

Separate support frame, Feed funnel 220 mm.

1x Pneumatic conveying system A4 V4 year 2018

1.0 m3 inverter-controlled ventilator for conveying materials.

Dimensions: Carding machine C70 : 230cm x 80cm x 250cm

Upper part pneumatic conveying A 4 V4 : 315cm x 95cm x 133cm

Down part pneumatic conveying A 4 V4 : 230cm x 80cm x 250cm

Condenser : 182cm x 100cm x 250cm

Sliver potting unit : 190cm x 115cm x 225cm

Yellow Crawn tool : 315cm x 95cm x 133cm (can be dismantled)

Pallet with motor unit A 4V4 : 150cm x 90cm x 125cm

Wood box on yellow tool : 190cm x 110cm x 105cm

Large small wood box with 2 extra rails : 286cm x 35cm x 70cm

Yellow tool trolley : 170cm x 65cm x 115cm

Complete with extra spare parts, manuals, electrical schemes, set of Tools (yellow coloured) to install.

The condition of this installation is TOP. The mill installed the line back in 2018; in 2020 due to Covid they stopped production. Ever since they did not use the installation anymore so now, they decided to sell it.

AH82/050126D/YOR-YR/F/BC/

Barmag Oerlikon EAFK-PES-MULTI Texturizing(Site B)

Quantity: 1

Year: 2017 May

Model “EAFK-PES-MULTI”

288 spindles

SZ function (double disc friction)

Inverter type, Auto-doffing

Two Heaters

Heberlein jets

Additional tech details:

1- The machine is 2 sides, it means side A and side B, separately, LH+RH.

2- The machine JETS are Heberlein brand

3- INVERTER,

There are two typed of driving system as below:

(1). Individual Spindle Drive (e.g., Barmag FK, EFK, E-AFK, etc.) Structure and Control: Each spindle is driven individually by

a disc motor and controlled by an inverter (frequency converter).

The inverter regulates the rotation speed and torque for each spindle separately.

(2). Belt-Driven System (e.g., Murata 33H) Structure and Control: All spindles are driven by a single motor through a common belt system.

Speed is uniform across all spindles and is controlled by the main motor speed.

4- The RANGE OF DENIERS that these machines do range from 30 to 300d.

(1). Factory where the machine is mostly producing 75d and 150d, specially 300d.

for example 850rpm x 150d x 288sp x 24h x60 min. / 9,000 / 1,000 = 5,875.2 Kg x 30 days= 176,256Kg monthly per machine 288sp.

(2). With S-Z function(double disc), possible to produce 600d.

(In case of production for 600d with 300d by S-Z function,

productivity is 1.8 times higher than standard operation)

(3). In case of production with lycra device, productivity will be

decreased by 10 to 15%.

5- machine is made in China by Barmag of Germany (Assembled in China but with all key parts from Oerlikon-Barmag, Germany.)

6- This machine is in a SITE called SITE [B] and is partially working only, because they decided to stop soon machine by machine.

7- Machine can be inspected under power

8- machine is multispindles.

9- Heaters to be operated independently, so possible to work with single heater or two heaters

10- Machine has better quality PU type disc instead of ceramic disc.

AH82/050126D/RPL-RL/F/BC/

Oerlikon-Barmag Model “EAFK”(Site A)

Quantity: 1

Year 2012

288sp

Inverter type

Auto-doffing.

Two Heaters.

Additional tech details:

1- The machine is 2 sides, it means side A and side B, separately, LH+RH.

2- The machine JETS are Heberlein brand

3- INVERTER,

There are two typed of driving system as below:

(1). Individual Spindle Drive (e.g., Barmag FK, EFK, E-AFK, etc.) Structure and Control: Each spindle is driven individually by

a disc motor and controlled by an inverter (frequency converter).

The inverter regulates the rotation speed and torque for each spindle separately.

(2). Belt-Driven System (e.g., Murata 33H) Structure and Control: All spindles are driven by a single motor through a common belt system.

Speed is uniform across all spindles and is controlled by the main motor speed.

4- The RANGE OF DENIERS that these machines do range from 30 to 300d.

(1). Factory where the machine is mostly producing 75d and 150d, specially 300d.

for example 850rpm x 150d x 288sp x 24h x60 min. / 9,000 / 1,000 = 5,875.2 Kg x 30 days= 176,256Kg monthly per machine 288sp.

(2). With S-Z function(double disc), possible to produce 600d.

(In case of production for 600d with 300d by S-Z function,

productivity is 1.8 times higher than standard operation)

(3). In case of production with lycra device, productivity will be

decreased by 10 to 15%.

5- machine is made in China by Barmag of Germany

6- This machine is in a SITE called SITE [A] and is in full running in excellent condition.

7- Machine can be inspected under power

AH82/050126D/COL-CL/F/BC/

Barmag-Saurer Model Tex-Cocoon(Site A)

Quantity: 1

Year 2007

240sp

Inverter type

Manual-doffing

Two Heaters

Equipped with ‘Full Lycra Device’

Additional tech details:

1- The machine is 2 sides, it means side A and side B, separately, LH+RH.

2- The machine JETS are Heberlein brand

3- INVERTER,

There are two typed of driving system as below:

(1). Individual Spindle Drive (e.g., Barmag FK, EFK, E-AFK, etc.) Structure and Control: Each spindle is driven individually by

a disc motor and controlled by an inverter (frequency converter).

The inverter regulates the rotation speed and torque for each spindle separately.

(2). Belt-Driven System (e.g., Murata 33H) Structure and Control: All spindles are driven by a single motor through a common belt system.

Speed is uniform across all spindles and is controlled by the main motor speed.

4- The RANGE OF DENIERS that these machines do range from 30 to 300d.

(1). Factory where the machine is mostly producing 75d and 150d, specially 300d.

for example 850rpm x 150d x 288sp x 24h x 60 min. / 9,000 / 1,000 = 5,875.2 Kg x 30 days = 176,256Kg monthly per machine 288sp.

(2). With S-Z function(double disc), possible to produce 600d.

(In case of production for 600d with 300d by S-Z function,

productivity is 1.8 times higher than standard operation)

(3). In case of production with lycra device, productivity will be

decreased by 10 to 15%.

5- machine is made in China by Barmag of Germany

6- This machine is in a SITE called SITE [A] and is in full running in excellent condition.

7- Machine can be inspected under power

AH82/050126D/ARC-AC/F/BC/

Oerlikon Barmag EFK Texturizing(Site B)

Quantity: 1

Year 2011

240sp

Model EFK

Two heaters

Inverter type, Manual-doffing

Additional tech details:

1- The machine is 2 sides, it means side A and side B, separately, LH+RH.

2- The machine JETS are Heberlein brand

3- INVERTER,

There are two typed of driving system as below:

(1). Individual Spindle Drive (e.g., Barmag FK, EFK, E-AFK, etc.) Structure and Control: Each spindle is driven individually by

a disc motor and controlled by an inverter (frequency converter).

The inverter regulates the rotation speed and torque for each spindle separately.

(2). Belt-Driven System (e.g., Murata 33H) Structure and Control: All spindles are driven by a single motor through a common belt system.

Speed is uniform across all spindles and is controlled by the main motor speed.

4- The RANGE OF DENIERS that these machines do range from 30 to 300d.

(1). Factory where the machine is mostly producing 75d and 150d, specially 300d.

for example 850rpm x 150d x 288sp x 24h x60 min. / 9,000 / 1,000 = 5,875.2 Kg x 30 days= 176,256Kg monthly per machine 288sp.

(2). With S-Z function(double disc), possible to produce 600d.

(In case of production for 600d with 300d by S-Z function,

productivity is 1.8 times higher than standard operation)

(3). In case of production with lycra device, productivity will be

decreased by 10 to 15%.

5- machine is made in China by Barmag of Germany

6- This machine is in a SITE called SITE [B] and is partially working only, because they decided to stop soon machine by machine.

7- Machine can be inspected under power