AB54/240226/CL/

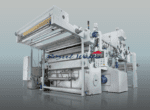

Lafer Line Model Waterless Scouring DISSOLVA

ALMOST NEW, Year: 2024

Lafer line model DISSOLVA, Width 220cm, to remove the oil from the knitting fabrics, 380Vts- 50HZ, Status: Stop in mill floor.

AA10/170226/

Osthoff Singeing

Quantity: 1, Year: 1996, Type U 94, Width 2m40, 2 ramps, 1 Brushing system, Entry roll exit roll.

AG52/130226D/OAT/M/AG/

SUCKER MULLER HACOBA Sizing Denim & Warping

SUCKER MULLER HACOBA Sizing Denim

Quantity: 1, Year: 2003, 14 BOXES DE COLOR E 2 BOXES DE ENGOMADO, 25-36 m/min, Width: 1.8 m

Sucker Muller Hacoba Warping

Quantity: 1, Year: 2003, Type: DIRECT WARPING 432 POSITIONS, 800 rpm, Width: 1.6 m

AJ04/090226/CV/

AUTOMATEX Canada

fully Automatic W/L and L/L 90 degrees corner fitted sheet sewing unit

Quantity: 1, Year: 2019, model FDC – 7735- B90D-EC, Unit description: the fabric coming from a roll via let -off goes automatically through tension control and edge guiding to the length hemming section ( with elastic insertion) After length measuring the fabric is cross cut and transported to the cross hemming section ( with elastic insertion ) After the hemming operation , the fabric of pre-formed with the side drop forming system. The rotational clamps then transfer the fitted sheet box to the corner sewing section, consisting of two left and two right sewing heads

Automatic lenght for European Flap Pillow Case Unit

Quantity: 1, Year: 2019, model FTO -6888 – T ( with 2 turners) The fabric coming from via let-off, goes automatically through guiding and accumulating the cross cutting section. After length measuring, the fabric is cross cut and transported through the hemming section consisting of one left and one right sewing head. After the hemming operation, the pieces are folded and transported to the side closing section consisting of one left and one right mock stitch sewing heads with latch tack. After the side closing, the finished pillow case are turned inside out and stacked on a bundle return conveyor. It is possible to apply both labels into the flap hem.

AF74/100226D/PS-A/F/

Mario Crosta Raising Machine

Quantity: 1, Year: 2018, Working width 2400mm, 2 drums, 28 rollers each

AJ04/090226/CV/

Confection Machines

1. BED COVER SEWING MACHINES WITH AUTOMATIC ELASTIC INSERTION

IN 4 CORNERS – RIMAC R3000-K3 = 5 pcs. Year 2006

The machines are equipped with a PEGASUS sewing head.

One operator can operate 2 machines where 650 covers can be made/8 hours/person or 1

machine where 376 pieces can be made/8 hours/person.

2. 1 pcs. sewing machine RIMAC -3000 – elastic insertion in corner and all around ,

head Juki

3. TAILORING MACHINE + ROLLER LIFTING CRANE , year 1999, – this consists

of the cutting table + the tools for arranging the fabric on the table and cutting

4. Linear sewing machine , code 8300 N, 8500, 8700 Juki – 80 pcs

5. 1 needle and 3 thread overlock machines , Juki, – 3 pcs.

6. 2-needle, 5-thread overlock machines Juki MO 6716S , – 30 pcs.

-sewing speed= max 7000rpm

-needle spacing(gauge)= 4,8mm

7. Baratto sewing machines, year 2004 – 2 pcs.

8. Sewing machines surpiqure Juki , – 3 pcs.

9. Sewing machines surpiqure Brother – 5 pcs

10. Electronic sewing machine zig-zag Brother – 6 pcs.

11. Overlock machine SIRUBA 737Qe- 504M2 – 1 needle – 3 threads – 6 pcs.

12. Sewing machines for buttons Jack- 2 pcs.

13. Sewing machine for buttonhole Juki – 1 pcs.

14. Sewing machine for buttonhole Jack – 3 pcs.

15. Sewing machine Pegasus – bourdon – 13 pcs

AJ04/090226/CV/

Confection Machines

1. BED COVER SEWING MACHINES WITH AUTOMATIC ELASTIC INSERTION

IN 4 CORNERS – RIMAC R3000-K3 = 5 pcs. Year 2006

The machines are equipped with a PEGASUS sewing head.

One operator can operate 2 machines where 650 covers can be made/8 hours/person or 1

machine where 376 pieces can be made/8 hours/person.

2. TAILORING MACHINE + ROLLER LIFTING CRANE , year 1999, – this consists

of the cutting table + the tools for arranging the fabric on the table and cutting

3. 2-HEAD AND 5-THREAD OVERFILL MACHINES , year 2014

4. JUKI –MO 6716S, year 2006 = 10 machines

-sewing speed= max 7000rpm

-needle spacing(gauge)= 4,8mm

AJ04/090226E/P-A/F/CV/

SINGEING MACHINE IN.TES, Italy,

Quantity: 1, Year: 1991, working width 270 cm, The singeing machine uses controlled flames to burn away

loose fibers and fuzz from fabric surfaces, creating a smoother and more refined

material for better dyeing and finishing. Machine functional.

AJ04/090226E/AC-A/F/CV/

MATHIS laboratory mini-jigger

QUANTITY: 1, YEAR: 2005, Type WJ 15009- 350 , The WJ jigger is a closed-type laboratory dyeing machine for textiles (and blends).

Being closed allows the use of reduction agents in the dye bath safely.

It is used for exhaust dyeing of fabrics under controlled conditions, especially at

laboratory scale to simulate and test dyeing processes.

«WJ» 350, «WJ» 500

Roller width : 350 mm, Batching diameter: 150 mm, Material speed : 0.5 – 10 rpm

Material tension : infinitely adjustable, Temperature range : 20 – 95 °C

Liquor content min. : 400 ml, Liquor ratio to : 1:3

Cooling: Cold water, Program selection: Time-controlled, endless, passage counter

Dimensions: W x D x H 890 x 600 x 620 mm, Weight ~105 kg

AJ04/090226E/AYL-AR/F/CV/

MONTI MAC ITALY

Quantity: 1

Year: 2013

1 pcs. Grey preparation line – model 1090,Italy

1 pcs SUPERAUTOMATIC DOUBLING FOLDING AND MEASURING MACHINE

MODEL LAFRA 200 TDD on pallets base version, 1 pcs HEAD TO HEAD sewing machine on movable stand 1 set

Description : GREY PREPARATION LINE – mod 1090, Fabric width from 1800 mm up to 3000 mm, Kind of fabric – 100 % cotton for BED LINEN – dry condition

Kind of sewing – BUTTED seam 1 needle, 1 thread, with reinforced stitch on both edges.

Fabric inlet : Pallet with OPEN Width and double in fabric, Bales with Open width and double in fabric

• Cradle to contain fabric rolls having maximum diameter up to 500 mm

• Sewing rail mod. TA21-3FY : For fabric head to head sewing butted seam sewing

machine that makes a sewing straight and flat

• Inspection table with upper light equipped

• Brushing device with 2 motorized brushes, installed in a steel painted cabinet.

• Dust vacuum: Suction unit made by centrifugal fan and filters.

• Selvedge shifting during the up rolling operation.

• Fabric delivery: in roll.

Description of : SUPERAUTOMATIC DOUBLING FOLDING AND MEASURING

MACHINE MODEL LAFRA 200 TDD on pallets base version, General features

Useful width of the doubling triangle 3200 mm, Useful width of the machine 1600 mm, Folded material pack, max height 2000 mm

Material unwinding from big rolls, small rolls, from folds

Measuring: In the machine 3 measuring systems are placed: one mechanical fold

counter to give the total measuring of the folded pack, an electronic one to give the control

measure for daily or weekly production and an electronic count-meter to give the total meters

of the palletized cloth.

Material stocking: Whether is doubled or openly folded, is prepared in perfectly

squared pallets up to 2.000mm height form the floor(ground)

The table descent is automatic and controlled by an oleo dynamic device that, enables

a constant and automatic lowering. The maximum capacity by the table is about 1500kg.

Description of : HEAD TO HEAD sewing machine on movable stand 1 set

Head to head sewing machine with movable stand model TU03/105

Butt seam sewing head model TC 105 E- 44 Volt

1 pcs Movable stand on wheels model TU03- 220 V

AD63/100226/

MARIO CROSTA Raising Line

Quantity: 2, Year: 1994, Model: MC10/36, Width of Raising rollers: 1800 mm., Number of Raising Cylinders: 36 per machine, Stainless steel gaskets for wool fabric, Machines equipped with inverter

AA23/090226/AZ/

Mario Crosta Raising Machines

Quantity: 2, Year: 1997-1998, Model NSC/AMJ, w.width 200cm.

20 ROLLERS PER MACHINE, ROLLER WIDTH 220CM, VERY LITTLE USED, PILE AND COUNTER PILE – FRONT AND BACK SIDE RAISING IN ONE PASS. SUCTION INCLUDED.

AA23/090226E/YP-Y/M/AZ/

Year: 1998

AA23/090226E/YY-Y/M/AZ/

Year: 1997

AB55/040226D/AYI-O/C/AT

Osthoff Singeing Range

Quantity: 1, Year: 1999 (Upgraded in 2018), Burners: Brand new burners installed in 2018, Electronics: Siemens electronics and HMI installed in 2018, Roller Width: 2000 mm, Model: VP 97, Line Configuration & Features: Entry with J-Scray, Pre-Brushing Unit, Osthoff Dual Burner Section, Post-Brushing Unit, Brugman Desizing & Washing Unit, Exit with J-Scray, Surface-Driven Motorized Batcher.

Machine is in Excellent Condition

Installed on Mill Floor

Burner in electronic installed new in 2018 Euro 185,000 spent at that time.

AF45/020226E/YO-O/F/BY

CARU Sueding Machine “S 330”

Year: 2017

1 set Pattern Sueding machine

type “S 330”

2400 mm table width included:

Out let with big batch roller / plaiter;

Suction unit with motor fan and filter bags unit;

Chiller unit for sueding roller;

PLC and Touch-screen;

Emery paper clamping and auto-tensioning system,

to install easily the emery paper on the sueding roller. (PATENT)

Production Speed:

Variable from 5 meters per minute to 15 meters per minute

Additional:

3 pcs rubber roller;

5 sets of emery paper rolls

1 set laser engraving machine 1

type “LSC 120”

3200mm table width

included:

adjustable focus distance,

exhausting suction fan,

PLC for axis control,

computer system unit,

monitor 19” Touch screen,

internet tele-assistance.

LSC 120 TECHNICAL FEATURES

Table width: 3200 mm / Electric power installed kW 3

Working width: 3000 mm / Tension 400 Volt

Dimensions 0,8 x 3,5 x H 1,5mt / Frequency 50 Hz

Weight 580 kg / Cooling system Air

Laser power 120 Watt / Fast Rise and Fall Time <75ìs

Air pressure consump. 25Nl/h / Air pressure 5 bar

Machine with less working hours

The sueding machine “S 330” is made up of one sueding roller which, contrasted to a roller covered with rubber, let’s to sue de fabric.

Pattern sueding effects;

In this case the roller covered with rubber has to be replaced with a roller engraved with the drawing (patterns) which has to be reproduced on fabric.

Other materials like knitted fabric, imitation leather and nonwoven fabric can be processed given an excellent finishing quality.

AD76/020226D/ASL-AI/F/AS

Osthoff Singeing

330 cm working width

2005 model

2 burners

Fabric opener, brush, dust suction, singeing unit, desizing tank, batcher,

CONDITION : Installed and running situation

AD63/290126/

Kuesters Bleaching Line

Year: 1991

7 tanks with steamer

Roller width: entry 4.000 mm, delivery 3.800 mm.

Useful working width: entry 3.800 mm, delivery 3.600 mm.

Production speed: up to 120 m/min.

Entry fabric from big batch with E+L selvedge widener mod. KF 2020 L

No. 1 washing tank model Compacta-D with fabric content 30 mt., useful working width 3.800 mm.

No. 1 squeezer mangle with two cylinders, type 225.23, useful working width 3.800 mm.

No. 1 washing tank model Maander with fabric content 15 m, useful working width 3.800 mm.

No. 1 cooling tank, useful working width 3.800 mm.

No. 1 high-performance two cylinders strong squeezer mangle with floating cylinder, type 222.56, useful working width 3.600 mm.

No. 1 impregnation tank to saturate the fabric, useful working width 3.600 mm.

No. 1 squeezer mangle with two cylinders, type 225.23, useful working width 3.600 mm.

No. 1 roller-bed vaporizer type 242.52, useful width 3.600 mm., with the following fabric loading capacities: 84 linear meters of cylinder fabric threading and 1.900 linear meters of fabric on the roller-bed. Date calculated with 150 gr./m2 fabrics.

No. 1 washing tank type 235.29 applied to the vaporizer, useful width 3.600 mm.

No. 1 squeezer mangle with two cylinders, type 225.23, useful working width 3.600 mm.

No. 1 washing tank model Compacta-D, useful working width 3.600 mm., fabric content 20 mt.

No. 1 squeezer mangle with two cylinders, type 225.23, useful working width 3.600 mm.

No. 1 washing tank model Maander, useful working width 3.600 mm., fabric content 15 m.

No. 1 squeezer mangle with two cylinders, type 225.23, useful working width 3.600 mm.

No. 1 washing tank model Maander, useful working width 3.600 mm.

No. 1 cooling tank, useful width 3.600 mm.

No. 1 high-performance two cylinders strong squeezer mangle with floating cylinder, type 222.56, useful working width 3.600 mm.

Fabric delivery in big roll with tangential winding

Electrical cabinet

Updated control pulpit with new screens

No. 2 heat recovery units.

AD63/290126/

Babcock Bleaching Line

Quantity: 1, Year: 1995, n. 7 tanks, steamer, roller-bed, working width 1800 mm, Useful working width: 1800 mm., Fabric entry from big roll with axial unwinding, J-box for fabric accumulation, N. 2 preparation tanks, N. 1 saturator tank model “ECONSAT”

N. 1 rollers steamer with about 60 meters of fabric content + roller-bed with up to 250 mt. of fabric content

N. 3 washing and rinsing tanks, N. 1 final neutralization tank for acid or for optical white

J-box for fabric accumulation, Fabric exit in big roll with tangential winding, Automatic dosing system for chemical products, Water system on board the machine, Steam system on board the machine, Electrical and pneumatic system on board the machine

AD63/290126/

Lafer Equalizing For Knitting And Woven Fabrics

Quantity: 1, Year: 2017 , roller width 2600 mm, Model: AZL, Rollers width: 2.600 mm

Useful working width: 2.400 mm, Fabric entry from a plate or big roll with manually adjustable fabric brake, Double motorized spreader

Motorized centring device, Selvedge opening device (similar to Tandematic), Feelers and overfeed wheels

Vertical pin chain, Four round silicone rubber belts supporting the fabric along the entire length of the chain to prevent sagging, especially on lightweight fabrics, One steaming field, Cooling belt with double suction, Fabric delivery in plate

AD63/290126/

Aigle Continuous Flocking Line, with Reggiani Printing Roller and Stork Oven

Quantity: 1, Year: 1992, Working width: 1.900 mm.

Composition:

REGGIANI printing roller, working width 1.980 mm, with washing system with water and doctor blades.

Nomex carpet for transport the fabric

Doctor blades for printing roller with feeding pump

N. 2 flocking units AIGLE working width 1.900 mm

Glitter’s spreader unit working width 1.900 mm

N. 2 suction unites for flock fibers

Brushing unit

STORK oven, gas heated, with N. 3 section. The oven can work with N. 3 passage of about 25 meters, or with single passage of about 9 meters.

AD63/290126E/RIC-AO/F/AQ/

OMAS Combined Milling And Scouring Machine NEW For Rope Fabrics

Year: 2023 – the machine is new yet to be installed, Brand: OMAS (Italy), N. 4 channels, Model: NOBILTEX CF4, Number of channels: 4 independently adjustable, Milling cylinders with special rubber elements, Safety device for any nodes, Safety device to prevent slipping of the fabrics, Independent working pressure regulation for each channel, Product distribution system with independent liter-counter for each channel, Independent internal bath replenishment for each channela, Independent main tank drainage system for each channel, Rear tank for the preparation of the bath with inlet pump, Main motorization with 75 Kw servo-ventilated vector motor with ABB inverter, Machine is in prompt delivery.

AB08/280126/

Bianco Tubular Compactor

Quantity: 1, Year: 2013, Working width: 1’400mm, For tubular fabric with Nomex felts, Exit cooling field.

AA30/220126/AX/

Mario Crosta Fabric Raising Duplex

2 off 36 roller comprising:

A frame to feed to

Mario Costa 36 roller machine, Year 1999, Tension Unit

Mario Crosta 36 Roller machine, Year 1999, Batching to A frame

AC93/190126/

Osthoff Singeing & Impregnation Line

Quantity: 1, Year: 1998, Model: U 97, Rollers width: 2200 mm. Useful working width: 2000 mm., Fabric entry from big roll, Brushing machine with suction, Singeing machine with two burners, N.B. the bricks were changed a few months before closing and are as good as new, Beater machine with suction, Impregnation tank for desizing and/or bleaching in pad-batch, Fabric exit a big roll with tangential winding.

AB46/140126/

Babcock Wash/Scour Range

Quantity: 1, Year: 2001, Entry and exit rollers are 4.6m width

With 4 wash boxes (wash box 1 has 15 rolls, wash box 2 has 17 rolls, wash box 3 has 17 rolls, wash box 4 has 16 rolls)

Barco monitoring system

Menzel accumulator model 110PS01 year 2015 at entry, fed from A-frame with automatic unwinder, Menzel compensator with multiple rolls, potable water utilized in heat transfer process and dispensed to sewer, steam condensed and returned to condensate tank for reuse in boiler.

AE56/130126/BA/

Karl Mayer Sizing

Quantity: 1, Year: 2017, Width 360cm, Double tank working width 180cm, 5 creel, 12 pcs cylinder dia 800mm, Running condition.

AC93/070126/

Benninger Bleaching

QUANTITY: 1, YEAR 2003, ROLLER WIDTH 2.000 MM, ENTRANCE WITH J-SCRAY ACCUMULATOR, 2 IMPREGNATION TANKS, BENNINGER IMPACTA CHEMICAL DOSING UNIT, STEAMER, TIGHT STRAND, AND ROLLER BED PASSAGE, 3 TANKS BENNINGER EXTRACTA WASH RANGE, J-SCRAY ACCUMULATOR, EXIT BY FOLDER AND A-FRAME BATCHER.

AE56/070126D/AYL-AI/F/BA/

Biancalani Airo 24 Soften Machine

Quantity: 1, Year: 2023, Width 200 cm, Gas heated, Brand new and unused.

AB60/060126E/CYL-CI/M/AO/

Karl Mayer Beam to Beam Sizing

Quantity: 1, Year: 2018, Type: FILSIZE-S-F-1800, Beams 1800mm, Single-end sizing unit KARL MAYER rotal.

Single warp beam unroll device (The beam is driven by a motor and the tension is continuously controlled by a drum with a pressure cell, Length measurement, automatic diameter detection, motorised adjustable beam supports, hydraulic beam insertion and lift out system, tension 600N, min/max. diameter 300/1040mm), sizing bath type MPF for filament, Cooling device for the water-cooled sections, 2 air dryers type FA 6m (Hot air convection dryer), Separation of humid air by means of electric air aspiration, dryer type CD-F-7- with 7 dry cylinders all Teflon coated, waxing unit, beaming type BD, technical info: heating 220kW, Air temp 180)C (12 bar), water consumption 370 Kg/h, air circulation 8000m³/h @ 180°C, additional heater, Laserstop for yarn rupture, speed 500m/min, 600N, beaming head, command by KAMCOS Karl Mayer system.

NOTE: New price in 2018 : 578.000 Euro

Machine professionally dismantled and moved to warehouse. VIDEO OF THE MACHINE IS ON THE LINK.

AA30/060126/AX/

Brugman Continuous Rope Fabric Bleaching

Year: 1990

Range 3200mm

Stainless Steel

A Frame feed 3200mm

Osthoff-Senge Brushing and Singeing 3200mm Model PK86 no 624

With brushing 3200mm and vacuum unit

De-Sizing wash box 3200mm (Brugman)

2 x Stainless Steel Mixing tanks for enzymatic desize chemicals

Rope feed to:

4 off Greige Pit with traversing carriage

Wash tank no1. (All wash tanks 1200mm width for rope fabric)

Caustic Saturation

J box steamer no 1.

Wash tank no 2.

Wash tank no 3.

Sodium Hypochlorite Saturation unit

J Box no 2. for dwell (can be used with steam)

Wash tank no 4.

Peroxide saturation unit

J Box Steamer no 3. for final bleach process

Wash tank no 5.

Wash Tank no 6.

Pull Up unit with traversing carriage creel

5 off rope fabric storage pits

Croft pull up unit to:

Hall & Boyden Cloth Opener to 3200mm full width

Hall Boyden Squeeze Roller 3200mm

Drying Cylinders (25 off) 3200mm

Hall Boyden Batching unit 3200mm

8 off Stainless Steel chemical mixing tanks on new Stainless Steel Walkway

Notes:

The line with suitable guiders can be used for both single width and 3200mm fabric.

Greige Fabric Brushing and Knocking 3200mm comprising:

Bailing Conveyor – Length Entry track – 7.25mtrs – Coveyor belt 9.5mtrs – Unpacking table 80cm – Belt width 134cm

Brushing/Knocking unit 3200mm

Fabric openers for wide width fabric and Bianco internal fabric guiding unit. A frame batching Batching frame 3200mm.

AE56/311225/

Lafer Brushing /Sueding Machine

Quantity: 1, Year: 2012,Italy origin, 220cm working width.

AB72/281225/

Osthoff Singeing Range

QUANTITY: 1

YEAR: 2001

WW 1850 MM

ROLLER WIDTH MM.2000 (WORKING WIDTHMM.1850 )

MACHINE HAS HAD THE BURNERS OVERHAULED WITH BRAND NEW FIRE BRICS 2 YEARS AGO SO THE HEART OF THEMACHINE IS LIKE 2 YEARS OLD.

CONSISTING OF:

ENTRY FRAME WITH GUIDING BRUSHING-BEATING UNIT MADE IN STAINLESS STEEL

OSTHOFF SINGEING – MODEL U 97 BURNERS TYPE DOUBLE-JET

4 WATER COOLED ROLLERS WITH AUTOMATIC SELF-BURNER TURNING DEVICE ON E STOP OF MACHINE. THE BURNERS HAVE THREE WORKING POSITIONS:

WITH FOLLOWING ADJUSTABLE PARAMETERS:- FLAME HIGHT – FLAME WIDTH – FLAME INTENSITY.

N.1 OSTHOFF BRUSHING / BEATING UNIT –MODEL VP 97 – WITH

N. 02 BRUSHES CYLINDERS AND

N. 02 OSTHOFF SINGE UNIT WITH 2BURNERS TYPE U 97 WITH FLAME QUENCH SYSTEM

N. 02 BEATERS CYLINDER- WITH SUCTION DEVICE

N.1 OSTHOFF EXIT WITH PLAITER UNIT DRIVEN BY A/C MOTOR

N.1 MAIN CONTROL PANEL WITH AC FREQUENCY INVERTERS

N.1 OPERATORS REMOTE STATION WITH ALL CONTROL PARAMETERS.

IN PERFECT WORKING CONDITION.

AB55/111225/

Brugman Double Stage Continuous Bleaching & Mercerizing Range

Quantity: 1, Year: 1999, Controls: Siemens PLC + HMI (installed new in 2018), Working Width: 2000 mm, Bleaching Line Configuration, Entry with J-Scray, 2 Pre-Wash Boxes, Heavy Duty Squeezer, Brugman Double-Stage Steaming Chamber, 3 Post-Wash Boxes, Direct exit into Mercerizer section, Brugman Roller , Mercerizer, Mercerizing Section, 16 Double Rollers (16 Up + 16 Down), Stabilizing Section, 11 Double Rollers (11 Up + 11 Down), Post-Wash Section, 3 Boxes (Washing → Neutralization → Wash-off), Drying Section, 18-Cylinder Dryer Range, Exit, J-Scray and Batcher

AB55/111225/

Goller/Monforts Caustifier & Washing Range

Quantity: 1, Year: 2016, Working Width: 2000 mm, Range Configuration, Monforts Caustifier Unit, Pleva Moisture Control, Goller Washing Section: 4 Sections, Brugman Washing Section: 6 Wash Boxes, Drying: 36-Cylinder Dryer Range.

AA10/051225/

Lamperti Raising

Quantity: 1, Year: 1995, mod. GHM/L93, w.width 2850 mm, 2 drums 24+24 cylinders, suitable for tubular knitting fabric.

AA10/051225/

Lamperti Sueding

Quantity: 1, Year: 2001, Model SMB, Brushes width 2400 mm. 3 vertical brushes, input from trolley, output folding system, without suction.

AA10/041225E/LY-Y/C/

Lafer Brushing

Quantity: 1, Year: 2002, mod.ULTRASOFT, Table width 2000 mm., 6 carbon brushes.

AB76/281125E/LC-L/F/BY/

Tumbler BIANCALANI AIRO DUE S

Quantity: 1, Year: 2001, Type AS2XGAE, Gas heating, 2 ropes, 2chambers, Capacity: 300 kg, Max temp. up to 200oC, Rollers for dragging fabrics, Processed fabrics: knit fabrics polyester, cotton, cotton with Lycra, For softening, various typed of knit fabrics, Machine in very good technical condition, running.

AB86/270925/

PAD STEAM EFI REGGIANI BLEACHING LINE

Quantity: 1 , Year: 2020, Table width 2000 mm, Maximum working width 1800 mm

Minimum working width 900 mm, Fabric composition: 100% cotton, Fabric weight: 80 to 250 GSM g/m2

Fine mechanical speed: 40 m/min, Production speed: 25 – 60 m/min, Voltage: 400 V AC +/- 10%, 50 Hz +/- 2%, Installed power: 73 kW, Pressure steam: 5.5 – 6 bar

Pressure compressed air: 6-7 bar, Compressed air consumption: 1.5 Nm3/hr, Pressure wash water: 2 – 3 bar, Water consumption: 6 – 8 lt/kg of fabric, Machine in Excellent condition

AA10/241125/

Lamperti Raising

Quantity: 1, Year: 1994, mod.GHM/L 93, Width 2200 mm. , 2 drums 24+24 cylinders, 3 wideners for each drum, Input and output on folding system on opposite sides, Inverter, Suitable for knitting fabric.

AE02/241125/

Goller Complexa Bleaching Line

Quantity: 1, Year: 2013, ww. 2400 mm (roller width 2600 mm), for open width knitted fabrics.

*AA27/221125/

Jaeggli Hanks Mercerizing

Quantity: 1

Year: 2000

Model: HL2000

Width: 1550 mm

Working Width: 1370 mm

Mercerizing machine for hanks of 54 “(rough reeling yarn), Model HL2000

-System compost from 2 separate compartments for the treatment of hanks in caustic soda, and two separated mobile compartments for washing.

-Electronic control of the position of the hooks and force, maximum capacity of 70ton

-Use up to 10 hooks of 1 kg. for total 10kg yarn for each work cycle.

– work cycle single mercerization, or double mercerization.

-Inputs for 3 wash water, three discharges separate, input to a caustic soda, pneumatically controlled.

– Each machine produces about 100 kg/h of hanks yarn 1Kg/cad. for a total of 800Kg to turn.

– 2 automatic loaders for hanks

– Hydraulic system 11Kw with control from, oil cooling system with water, hydraulic movements at variable flow control, with 4 hydraulic cylinders controlled in position encoders.

-Electrical panel with two doors with electronic PLC and Workstation control data work programs residents and selectable. Framework to a pneumatic door.

Construction year end 1999.

– A mixing plant for the preparation of caustic soda mercerization hanks, construction Switzerland manufactured by Merc-Control ag Kasag; model “Eco-Block”. Complete installation of the heat exchanger and circulation pump for the cooling of caustic soda, pneumatic control of the concentration with scale values Baume, suitable for work with two mercerizing. Construction year end 1999.

– A system for the separation of impurities present in the washing solution, such as spinning oils, wetting agents dispersed in the bathroom of lye, pectins and sugars derived from treated cellulose during mercerization. Manufactured by Merc-Control a.g. Kasag; model “Separator OAS.” Construction year end 1999.

*AA27/221125/

Jaeggli Hanks Mercerizing

Quantity: 1

Year: 2000

Model: HL2000

Width: 1550 mm

Working Width: 1370 mm

Mercerizing machine for hanks of 54 “(rough reeling yarn), Model HL2000

– Two compartments with caustic soda and two compartments for wash water collection

– The machine produce about 100 kg / h of yarn skeins 1Kg/cad. for a total of 800Kg. per shift.

– Autoloaders

– Hydraulic system shot with variable flow control, with 4 pistons firing control with encoder

– Yarn type: cotton & all cellulosics fibers

– Nominal hanks size: 1370 mm

– Hanks size: 1180/1510 mm

– Max. loading capacity: 12 kg/cycle

– Electronic control of the position of the hooks and force, maximum capacity of 70ton

– Use up to 10 hooks of 1 kg. for total 10kg yarn for each work cycle.

– Work cycle single mercerization, or double mercerization.

– Inputs for 3 wash water, three discharges separate, input to a caustic soda, pneumatically controlled.

– 2 automatic loaders for hanks

– Hydraulic system 11Kw with control from, oil cooling system with water, hydraulic movements at variable flow control, with 4 hydraulic cylinders controlled in position encoders.

– Electrical panel with two doors with electronic PLC and Workstation control data work programs residents and selectable. Framework to a pneumatic door. Construction year end 1999.

– A mixing plant for the preparation of caustic soda mercerization hanks, construction Switzerland manufactured by Merc-Control ag Kasag; model “Eco-Block”. Complete installation of the heat exchanger and circulation pump for the cooling of caustic soda, pneumatic control of the concentration with scale values Baume, suitable for work with two mercerizing. Construction year end 1999.

– A system for the separation of impurities present in the washing solution, such as spinning oils, wetting agents dispersed in the bathroom of lye, pectins and sugars derived from treated cellulose during mercerization. Manufactured by Merc-Control a.g. Kasag; model “Separator OAS.” Construction year end 1999.

AB45/191125/

Biella Continious Steaming Shrinking Machine

Quantity: 1, Year: 2002, model Ecovap 95

Cylinder width 1900 mm

Machine with Igrofast system and carbon brush builded in.

Igrofast drastically reduce used steam quantity

Vibro shrunk with humidifier ECOVAP KD

Suction and fans (ventilators) included

AA02/101125/

TERRY WEAVE PLANT

WARPING

1 KARL MAYER DIRECT WARPER

Year: 2018

Model Warp Direct 2400/1250

With

1 KARL MAYER VEE CREEL

Year: 2018

Model Creel

650 Running ends

1 TANGSHI CONE TO CONE RE-WINDER

Year: 2018

60 positions Double sided 30 positions each side

SLASHER SIZING

1 KARL MAYER SIZING MACHINE

Year: 2018

Model Pro-Size

3.8 meter maximum Warp width

BEAM HANDLING

2 WUXI XJANDA BEAM STORAGE RACKS

Year: 2018

16 WUXI XJANDA BEAM TRANSPORT TRUCKS

Year: 2018

WEAVING

24 TOYOTA AIR JET TERRY LOOMS

Year: 2018

Model JAT810

Type JA4T-280DE-EH-T810

280cm weaving width

4 color, Staubli dobby Model S3222 e3 DRC

1 LUWA OVRERHEAD TRAVELLING CLEANING SYSTEM

Year: 2018

4 Blower Heads

Each With Tracking covering 6 Looms 280cm

1 GROZ-BECKEART WARP TYING HEAD

Year: 2018

Model Knot Master

72 SPARE PILE BEAMS

48 SPARE GROUND BEAMS

90 SPARE NEW LIFE HARNESS FRAMES

72 TOYOTA LOOMS WEAVING CLOTH ROLLS

AB72/071125/

IMPIANTI CONTINUI (ISOTEX) COATING RANGE

QUANTITY: 1

YEAR: 2002

WORKING WIDTH 2300MM

REFRURBISHED IN 2023 FITTED WITH NEW BURNERS ENTRY IN FEED SECTION 2 – CENTRE UNWIND STATIONS FOR A – FRAME BATCHES. 1 BIRCH MERROW TRAVERSING SEWING MACHINE. 1 INLET ACCUMULATOR 50 METERS FABRIC CONTENT 1 E+L CENTRALISING GUIDER 1 FINE TRIM LOAD CELL COMPENSATOR COATING 1 ISOTEX KNIFE OVER ROLLER COATING HEAD WITH THE OPTION TO COAT KNIFE OVER HOLLOW BED, OPERATORS PLATFORM, VIA 2 X 316 SS PATH ROLLERS, ON TO ADJUSTABLE COATING ROLLER, MICRO ADJUSTABLE COATING HEAD WITH DOUBLE SIDED COATING BLADE, TRAVERSING COMPOUND FEEDER, ADJUSTABLE SIDE DAMS, AC VARIABLE SPEED DRIVE WITH AUTO MANUAL CONTROLS, HIGH SPECIFICATION SAFETY INTERLOCKS IN ACCORDANCE WITH CE REGULATIONS. QUALITY COATING WEIGHT CONTROL SCANNING SYSTEM. 4 REINHARDT TECHNIK COMPOUND MIXING STATIONS TYPE ZFE 200L YEAR 2004 DRYING AND CURING ISOTEX SINGLE PASS DRYING OVEN 7 CHAMBERS DIRECT GAS HEATED COMPLETE WITH EXHAUST SYSTEM. TOP COATING UNIT ONE COATING HEAD AND ONE CHAMBER DIRECT GAS HEATED COMPLETE WITH EXHAUST SYSTEM EXIT OUTLET SECTION 2- COOLING ROLLERS 1 E+L CENTRALISING GUIDER 1 FINE TRIM LOAD CELL COMPENSATOR 2 – OPERATORS PLATFORM ONE WITH INSPECTION BACK LIGHTING. 1 OUT LET EXIT ACCUMULATOR 50 METERS FABRIC CONTENT 1 – CENTRE RE – WIND STATION FOR A – FRAME BATCHES.

AI86/311025/AS/

Leo Sistig Velvet Brushing – Pol-Rotor – Shearing Machine

Renovated in 2023. A comprehensive overhaul was carried out. Complete mechanical and electrical overhauls were completed, and the machine is now fully operational.