AG52/121125/BS/

Rieter Complete Cotton Spinning Line

Rieter E30 Unilap:

Quantity: 1, Year: 1999, Machine with feed for 28 cans, diameter 600 x 1,200 mm. Core dimensions: inner diameter 180 mm, outer diameter 200 mm, and length 300 mm. Semi-automatic lap delivery system to the comber, with Servo Trolley system.

Rieter E60-E62 Combers:

Quantity: 8, Year: 1997-1999, 8 combing heads equipped with automatic lap change system. Fixed comb Rieter Ri-Q-Top. Automatic can changer. Designed for upward air exhaust. High-performance lightweight alloy nippers with feed rollers for forward and backward motion. Detaching rollers with pneumatic pressure. Drafting system 3 X 3.

Rieter K45 Ring Spinning Frame:

Quantity: 7, Year: 2008, 1,632 spindles, ComforSpin machine – yarn compacting system. Drafting system driven by individual motors. Total draft programmed via control panel. Pre-draft by toothed gears. Drafting system with compaction zone. Double apron drafting system with pendulum arm type P 3.1, pneumatically loaded. Compaction zone with perforated and suction drums, with special surface finish. Spindle gauge: 70 mm. Flange 1 Titan ring, diameter 40 mm.

Rieter G33-G35 Ring Spinning Frame:

1x Model G33 = 1,200 spindles / Year 1999

8x Model G35 = 1,632 spindles / Year 2008

Spindle gauge: 70 mm. Suction unit installed at the machine head. Spindle drive motor. Intermediate drive for fluted roller. Drafting driven on both sides by 4 motors with respective gears. Maximum bobbin diameter: 7 inches. Bobbin lift: 16 inches. 3-roller drafting system with pneumatic pressure. Flange 1 Titan rings, 42 mm. Tube length: 210 mm. Internal diameter: 18 mm.

Rieter F30 Roving Frame:

Quantity: 1, Year: 1999, Machine with 120 spindles. Flyer diameter: 6 x 16 inches. Automatic doffing. Drafting system 3 over 3. Designed to accommodate 500 mm cans. Main motor controlled by inverter.

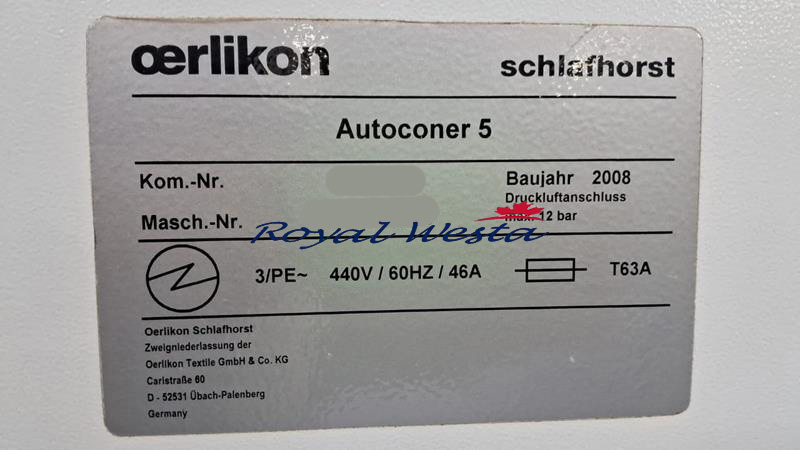

Saurer Autoconer AC5:

Quantity: 15, Year: 2008, 34 spindles / 32 spindles. Cone winder with winding angle 4°20’ (conical). Traverse drum system with yarn waxing device. Electronic clearer Loepfe Zenit. Air-splicing device for yarn joining.

Factory maintain the machine on best way possible and makes highest quality yarn.

5 sets of G35 & AC5 that were dismantled in June 2025.

1 set of K45 + AC5 autoconer dismantled in June 2025.

1 or 2 sets of G35 & AC5 will be dismantled in Jan 2026 - machines are in production until then.

6 or 7 sets of K45 & AC5 will be dismantled in Jan 2026 - machines are in production until then.