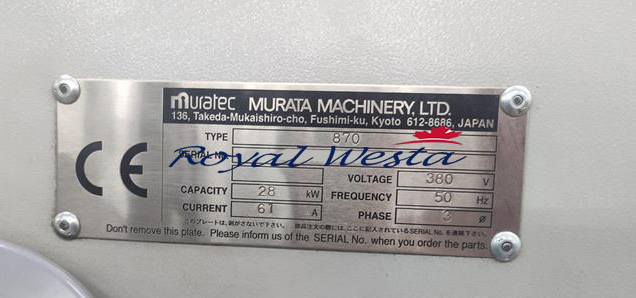

AI40/181224D/SO-O/M/

Murata Vortex 870

Quantity: 22

80 Spindles

Specifications:

Single deck and single side, Machine Direction ( Right or Left Hland) is selectable,

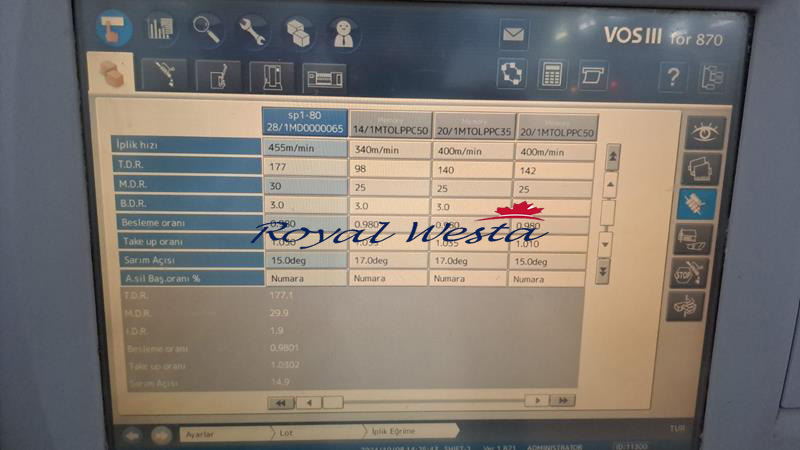

VORTEX spinning unit, 4 lines drafting system, STS ( Spinning Tension Stabilizing) system spinning speed range is mechanically 300-500m/min. Max. package dia.=300mm, 235mm unit pitch

equipped with Dust box, Spinning speed meter, Air control panel, Auto doffer, Package indicator for random doffing, and including all necessary motors, but without air compressor and air piping.

Sliver cans size : 18 inch 0. D.

Total Draft Ratio mechanically: 100 - 450

Standard Equipment:

For each spindle: 2 types of Spinning Nozzle / 2 types of Needle Holder / 4 types of Spindle

Sliver creel with guide

High ratio 4 line drafting unit with 3rd and 4th Back Roller individual control.

High speed VORTEX spinning system I New designed spinning components.

Self spinning system I complete individual start spinning.

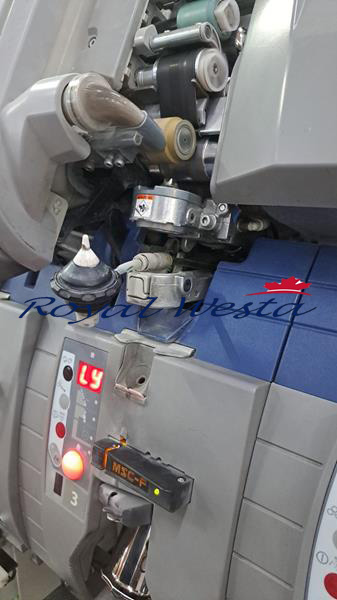

Alarm indicator and operation keys on each unit

MSC-F (Muratec Spin Clearer with Foreign Fiber Detectionion)

Spinning sensor for precision spinning condition monitoring

STS (Spinning Tension Stabilizing) system by new desixned Friction Roller

Splicer carriage "Type 87C" with Air splicing unit and head slide motion.(4 splicer carriages per machine)

Splice monitor for each splicer carriages

Waxing device

Over-head traveling cleaner

Individual drive Auto Dojfer "Type 87D" (I doffer per machine)

Automated bobbin stocker (for Max. 160 empty bobbins)

Yarn length measuring system

Package conveyor (Automatic conveyor Feed adjusment)

Individual inverter drive for all shaft and Energy saving blower motor

Vacuum chamber with Automatic waste fiber extraction system

VOS-Ill (Visual On Demand System)

Package lifter for all machines

Standard Spare parts & Special fools (2% of contract amount)

One machine requires 1x40' HC Ctr for shipment