Videos

Play / Download VideoAA19/101125E/LOO-RC/F/BY/

Befama Wool Scouring Line

Year: 2018

Mainly used for washing combed and carded wool that has not been spun.

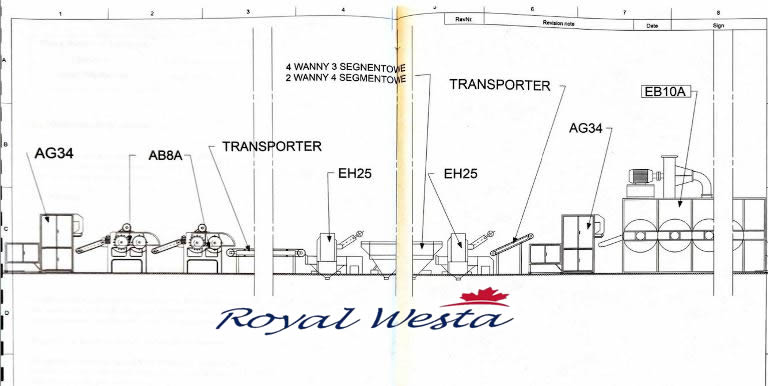

Set contents:

2x AG-34 loose fiber feeder.

1x AB8B double drum loosener.

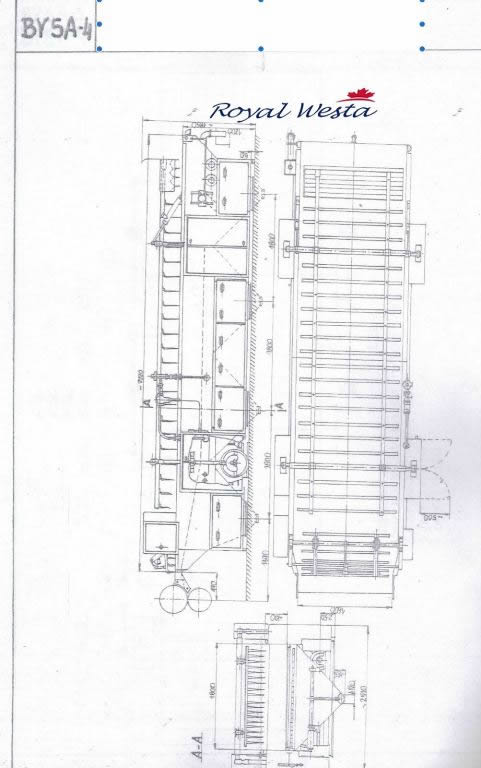

2x BY5A-4 washing vats.

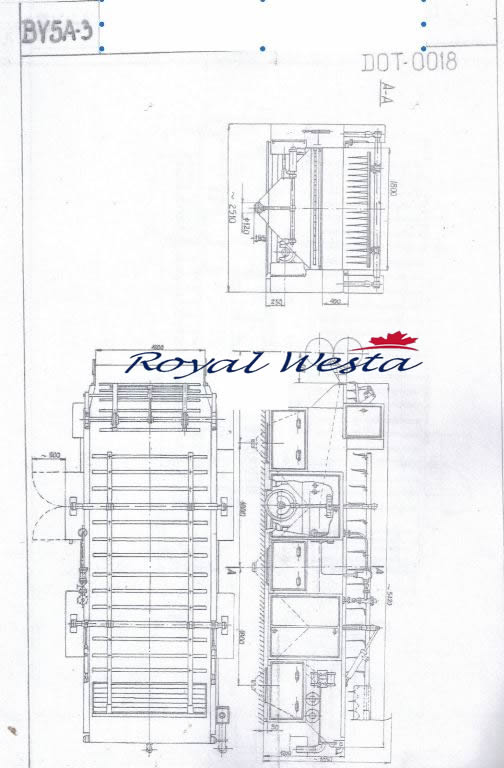

3x BY5A-3 washing vats.

5x EH9B wringer.

5x BU16 settling tank.

1x EB10A drum and flat screen station dryer.

1x Water recovery Installation.

Description of the pneumatic system

Equipped with a compressed air system, it is necessary to exert pressure on the squeezing shafts via pneumatic cylinders mounted on the EH9B squeezers.

The working air pressure during operation of the set should be between 7 and 10 atmospheres.

Each control cabinet used to control the wringers is equipped with an air pressure reduction valve, which can be used to adjust the pressure of the wringing shafts.

The user may use their own air compressors, provided that they supply a sufficient amount of air at a pressure of 7-10 atmospheres.

Description of electrical equipment

Control cabinets for powering and controlling electrical and pneumatic devices of individual machine groups included in the BS2A set

The supply voltage of the control cabinets is 230/380 V 50 Hz alternating current

Technical characteristics of the nominal set

The capacity of the BS2A washing set is between 300 and 600 kg/hour of washed wool with a moisture content of 15%.

For uniform wool with fleece edges containing up to 3% plant impurities and a minimum yield of 60% washed wool in relation to raw wool, and for the thickness specified in the standard, the following capacities can be achieved:

350: 400 kg/hour for wool with a thickness of 60/64 S and thinner

up to 500 kg/hour for wool with a thickness of 60 S and thicker

For mixed thin, medium, semi-thick, and thick wool, the yield ranges from 300 to 600 kg/hour, depending on the degree of matting and sanding.

Before washing, wool requires an additional process of loosening and scutching on a machine that is not included in the BS2A set.

During the wool washing process, mineral and grease contaminants are removed, while plant contaminants cannot be removed.

The above capacities are understood as net machine hours, i.e. without any auxiliary, technological, organizational, etc. downtime.

Water consumption according to industry standards is 15 kg / 1 kg of washed wool.

Steam consumption is approximately 1000 kg / hour.

Compressed air pressure from 7 to 10 atmospheres.

Working width of washing vats 1800 mm.

Installed power according to the attached electrical documentation.

Amount of water needed to fill BY5A washing vats and BU16 tubs once – 42 m³.

Dimensions:

length - 57600 mm

width - 4400 mm

height - 4400 mm

washing vats

BY5A vats are divided into BY5A-3 vats (4 pcs) and BY5A-4 vats (2 pcs) (drawings)

The difference lies in the number of segments that each of the above-mentioned vats consists of. The BY5A washing vat is of the harrow type, which means that the wool in the vat is moved by means of a large harrow and a small harrow, which picks the wool out of the vat and moves it to the lower roller of the wringer. The composition of the washing bath in the vat can be selected and adjusted using automatic detergent dispensers or manual valves installed on the detergent supply lines. The temperature of the washing bath in the vat can be maintained at the set level using manual valves that supply steam directly to the bath, or using thermostats that automatically regulate the supply of heating steam. Solid impurities that pass through the screens and settle at the bottom of each conical segment are removed by special drain valves that open automatically or manually.

The BY5A vat is equipped with a bath overflow device that can be used to regulate the bath level in the washing vat.

The washing bath in the vats circulates in a counter-current direction.

During washing, all vats should be supplied with water only in the fifth rinsing vat.

Each washing vat consists of segments welded from 5 mm thick $355 grade sheet metal, while the sixth vat is made of acid-resistant steel.

The sieves, combs, and drain trough are made of acid-resistant steel.

The wool throughput capacity of BY5A washing vats depends on the capacity of the entire BS2A washing set. For wool washed at 15% humidity, it ranges from 300 to 600 kg/hour.

AB8B double drum opening and scutching machine

Machine is primarily designed for loosening sweat wool in the BS2A washing set before the fibers enter the washing vats.

Machine can be used individually to loosen loose fibers, provided that they do not occur in the form of compacted flakes.

Technical data.

Working width 1600 mm.

Machine capacity approx. 1000 kg/hour.

Spiked drum rotation speed:

First drum 400 rpm.

Second drum 450 rpm.

EB10A drum and flat screen station dryer

EB 10A drum-screen dryer with a built-in feeder and a cross conveyor feeding washed wool – loose,

The feeder-dryer set is designed for drying wool after washing, after it has been loosened and spun, and is transported transversely to the feeder.

The dryer with feeder can be separated from the continuous system.

The average capacity of the dryer is 300 to 600 kg/h of dried wool.

The capacity depends on the initial moisture content of the wool, the efficiency of the heat exchangers, the speed of wool movement, and the method of water vapor removal.

Typically, the initial moisture content of the wool after washing is 85% and the final moisture content is 10-15%.

The dryer can also be used to dry other chemical fibers and cotton after bleaching and dyeing processes.

Heater specifications:

a) medium - steam

b) ref. temp./pressure [°C / bar] - 151/5

c) volume flow [M³/h] - 13600

d) mass flow [kg/h] - 36

e) power [KW/KJh] - 21.2/76390

f) inlet/outlet temp. [°C] - 151\ 151

g) permissible pressure [bar] - 10

h) max. temperature [°C] - 180

Overall dimensions of the dryer:

height 4087 mm

width 3450 mm

length 11095 mm

Installation of water recovery from washing machines for washing sheep's wool, including chemical dosing devices and automatic tub control systems.

The water recovery system is divided into five functional blocks:

1 Bag filtration unit

2 Water treatment unit

3 Flotation unit

4 Filtration unit

5Process line installation

Detergent dosing unit.

The water recovery system operates at a capacity of 1.0 m3/h.

Water for technological purposes is prepared in the water treatment unit. The water undergoes filtration and ion exchange softening processes. The station supplies the washing line, filtration unit, and dosing unit.

The washing line operates in a cascade system. Fresh softened water feeds the last process tank VI (manual control). If this tank is used for the process of neutralizing lye with acetic acid, the water will be fed to tank V. The quality of the final rinse depends on the flow rate of the rinse water. Excess water from the last rinse is pumped to the previous tank. The rinse water from the first rinse replenishes the bath losses in the last washing tub. The bath from the last washing tub replenishes the bath losses in the previous tub.

The bath composition is replenished by a detergent preparation and dosing system. The detergents used are soap dissolved in a sodium hydroxide solution and SANVIROL W22. The soap is dissolved manually in a dosing tank. The solution is heated and mixed without a diaphragm using steam.

NOTE: Machines are in very good condition, 100 % complete and still running in production