AA30/091225/AX/

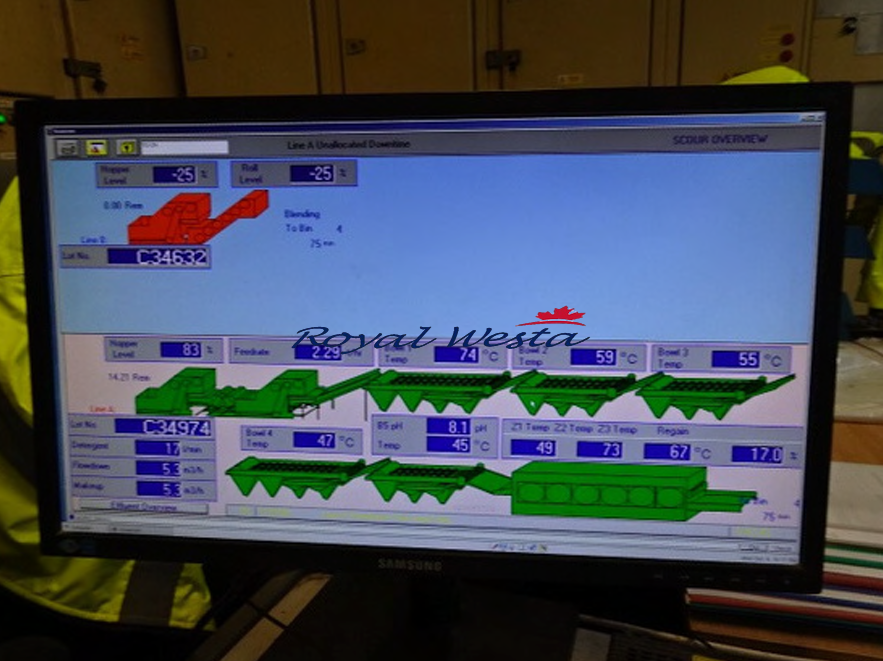

Andar Wool Scouring Line

A modern Stainless steel 5 bowl scouring line 2000mm wide 2300Kg capacity per hour manufactured by Andar New Zealand in 1990.

The machine is in continuous operation

ESTIMATE NO OF CONTAINERS FOR HOPPER, SCOUR, DRIER and walkway 16 to 20 off 40ft containers (some may require to be open top)

The 2300Kg per hour greasy wool input line is in continuous production daily until summer 2026 (when it will be replaced by a new 2500mm Scouring line)

ANDAR HOPPER 2000mm wide Year 1991

ANDAR WOOL SCOUR 5 BOWLS 2000mm wide Year 1991

ANDAR WOOL LATTICE DRYER 2400mm wide Year 1991

Details: 2000mm Andar Hopper 2000mm Wool scouring Weigh Belt Feed

Bowl 1 (18m3) Squeeze Roller 1

Bowl 2 (15m3) Squeeze Roller 2

Bowl 3 (15m3) Squeeze Roller 3

Bowl 4 (18m3) Squeeze Roller 4

Bowl 5 (15m3) Squeeze Roller 5

Andar Electrical Control Panel Triple crank rake mechanism Individual Gas red heating for each bowl Heavy solid dirt discharge valves

Drier: Andar Lattice Wool Dryer 2400mm 10 Gas burners, lattice conveyor

Exclusions not included: grease centrifuges, effluent treatment, water recycling are not included in the sale.

A full service of dismantling and loading of machinery and export services are provided

1. Power Requirements

Hopper , Hopper pin sheet 4kw, Motor 1.5 kw , Motor 0.75kw

BOWLS x 5 , 4kw squeeze press , 1.5 kw rakes , 1.1 kw other rakes , .55 sheets

circulating pump 4kw x 5

Dryer , 8 fans 15kw , 2 fans 18.5kw

Drum drive - 2 x 1.5kw

Blower motor 4kw x5

2. Labour Requirements, 4 workers total , 2 pickers , Scourer , Feeder

3. Dryer Output / Packing Machine, 1800kg / 2000kg Wool dependant

4. Water Input Wool dependant

5 litres per kilo.

5. Water Output / Waste Water Treatment, 3 to 4 litres per kilo.

None - ""mill retaining all water treatment""

6. Area Required for complete set up (60m long - 6m wide approx)